FTCO and Digital Twins

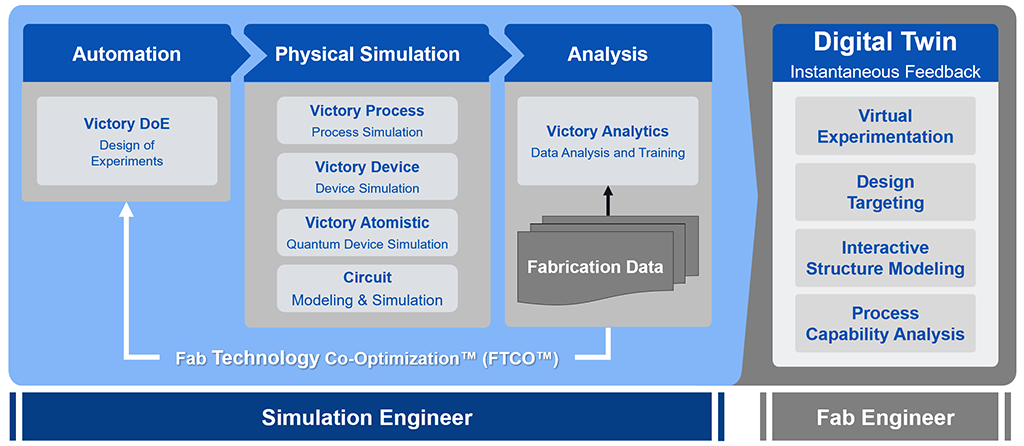

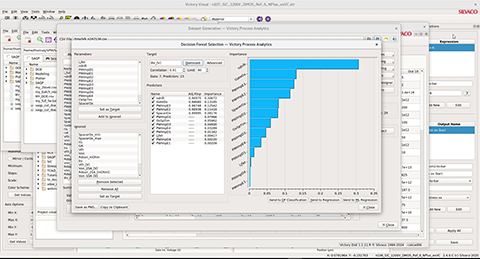

We have combined our expertise in semiconductor technologies with machine learning and data analysis to develop a solution named Fab Technology Co-Optimization, or FTCO™. FTCO™ enables a TCAD engineer to use artificial intelligence-based Victory Analytics and Victory DoE to setup and execute an iterative scheme for training a nonlinear model. This model represents the manufacturing process based on fabrication and physical process data from both simulation and experiment. Device and circuit simulations can be included in the training to automatically map correlations between process and device and circuit parameters. Once sufficiently trained, the model becomes a Digital Twin, encapsulating the entire knowledge embedded in the training data and the provided inputs from the TCAD simulation engineer.

AI-Driven FTCO™ Solution Platform Flow Diagram

Benefits

Minimizes cost and time to market, while maximizing production scale by reducing physical wafer learning cycles

Provides a smart and intuitive interface for non-TCAD simulation experts to get “hands on” manufacturability optimization in a virtual environment

Creates a platform of innovation for engineers to significantly reduce risks and accelerate time to market for their next-gen technologies

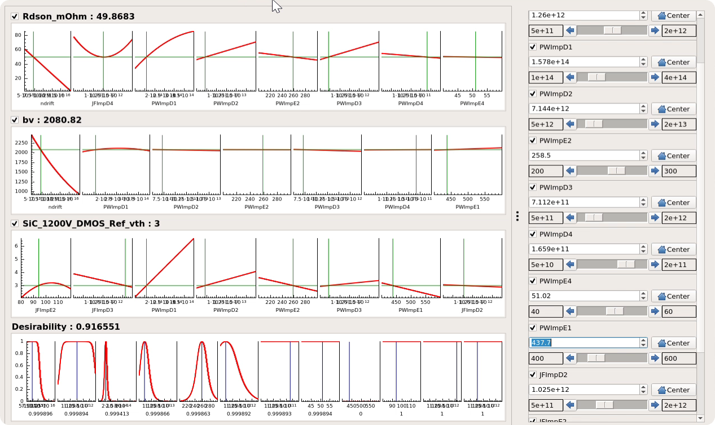

Virtual experimentation allows the engineer to study the correlations between process parameters and target design parameters by interacting with an intuitive and specially designed user interface for data analysis. Significant process parameters for user-defined design parameters are automatically highlighted. Example scenario: The engineer uses the Digital Twin to screen process and device target variables for a specific transistor. The real-time provided result shows that changing implantation doses strongly influences the threshold voltage but has negligible impact on breakdown voltage.

Design targeting allows the engineer to query the Digital Twin to provide optimal process parameter values for specific target design values. Parameter space exploration and identification of optimal process parameters is significantly accelerated. Example scenario: The engineer defines a target threshold voltage, and the Digital Twin returns the necessary doping doses to achieve the requested threshold voltage in real-time.

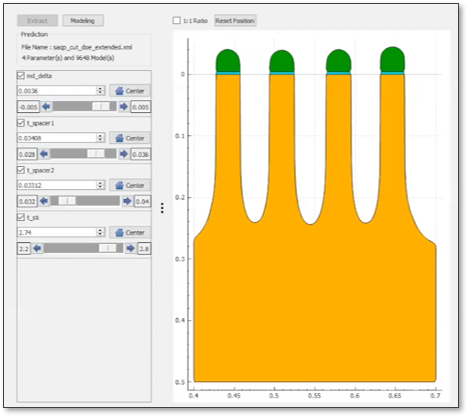

Interactive structure modeling allows the engineer to change process parameters and immediately have these changes visualized in the rendering window showing the structure. The presented output is indeed based on the physics-based training data and as such represents the physical reality with very high confidence. Example scenario: The engineer changes etching parameters and right away witnesses the impact on the shape of the etching profile.

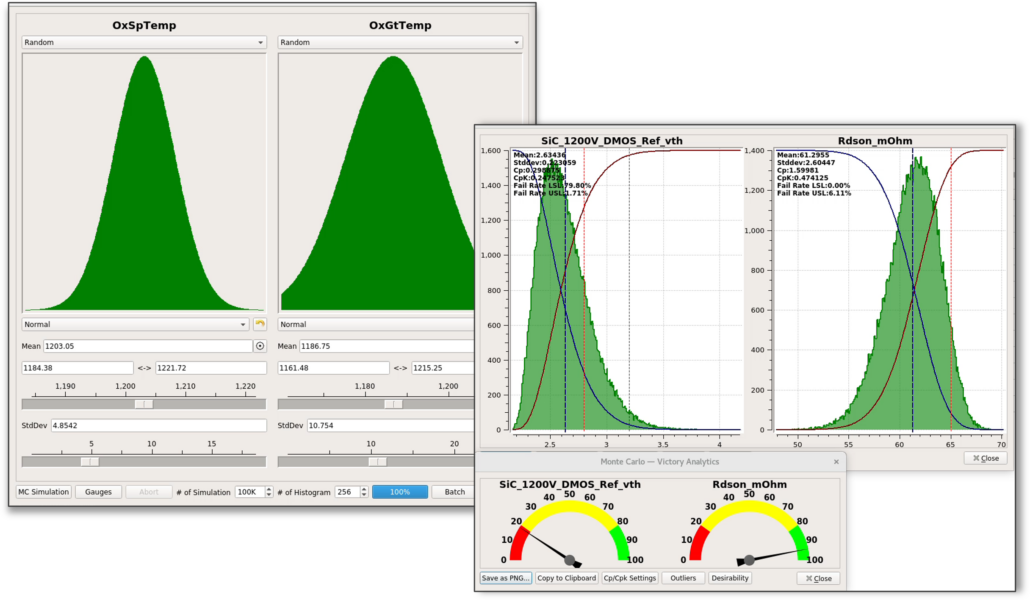

Process capability analysis allows the engineer to conduct parameter variation and yield studies by Monte Carlo and Cp/Cpk analyses. Example scenario: The engineer provides the Lot-to-Lot variation of the oxide thickness, and the Digital Twin provides the determined distributions of process and device metrics.

Developed in Collaboration with Micron Technology, Inc. to Optimize Memory Devices

Micron Technology, Inc. uses production data and physics-based simulation with a focus on etching, deposition, and mechanical stress in combination with Silvaco’s FTCOTM platform for data analysis and training of a Digital Twin model. The Digital Twin model allows for rapid and intuitive process, design, and yield optimizations also by non-TCAD engineers and accelerates design and pathfinding for memory product development.

Silvaco Announces Expanded Partnership with Micron Technology

Connect directly with an FTCO expert to learn more about using Silvaco AI-driven solutions to optimize processes, designs, and yields.

Dr. Gurtej Sandhu

Principal Fellow of Technology Pathfinding

Micron Technology, Inc.