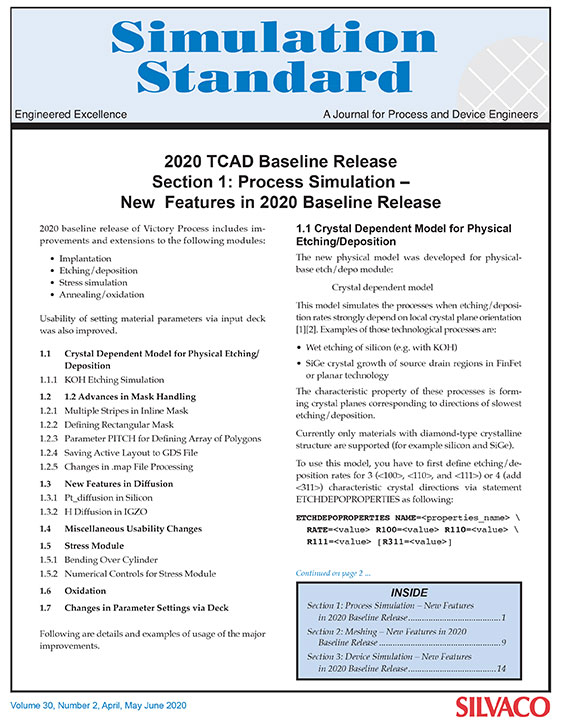

2020 TCAD Baseline Release

Section 1: Process Simulation – New Features in 2020 Baseline Release

2020 baseline release of Victory Process includes improvements and extensions to the following modules:

- Implantation

- Etching/deposition

- Stress simulation

- Annealing/oxidation

Usability of setting material parameters via input deck was also improved.

1.1 Crystal Dependent Model for Physical Etching/Deposition

1.1.1 KOH Etching Simulation

1.2 1.2 Advances in Mask Handling

1.2.1 Multiple Stripes in Inline Mask

1.2.2 Defining Rectangular Mask

1.2.3 Parameter PITCH for Defining Array of Polygons

1.2.4 Saving Active Layout to GDS File

1.2.5 Changes in .map File Processing

1.3 New Features in Diffusion

1.3.1 Pt_diffusion in Silicon

1.3.2 H Diffusion in IGZO

1.4 Miscellaneous Usability Changes

1.5 Stress Module

1.5.1 Bending Over Cylinder

1.5.2 Numerical Controls for Stress Module

1.6 Oxidation

1.7 Changes in Parameter Settings via Deck

Following are details and examples of usage of the major improvements.

1.1 Crystal Dependent Model for Physical Etching/Deposition

The new physical model was developed for physicalbase etch/depo module:

Crystal dependent model

This model simulates the processes when etching/deposition rates strongly depend on local crystal plane orientation [1][2]. Examples of those technological processes are:

- Wet etching of silicon (e.g. with KOH)

- SiGe crystal growth of source drain regions in FinFet or planar technology