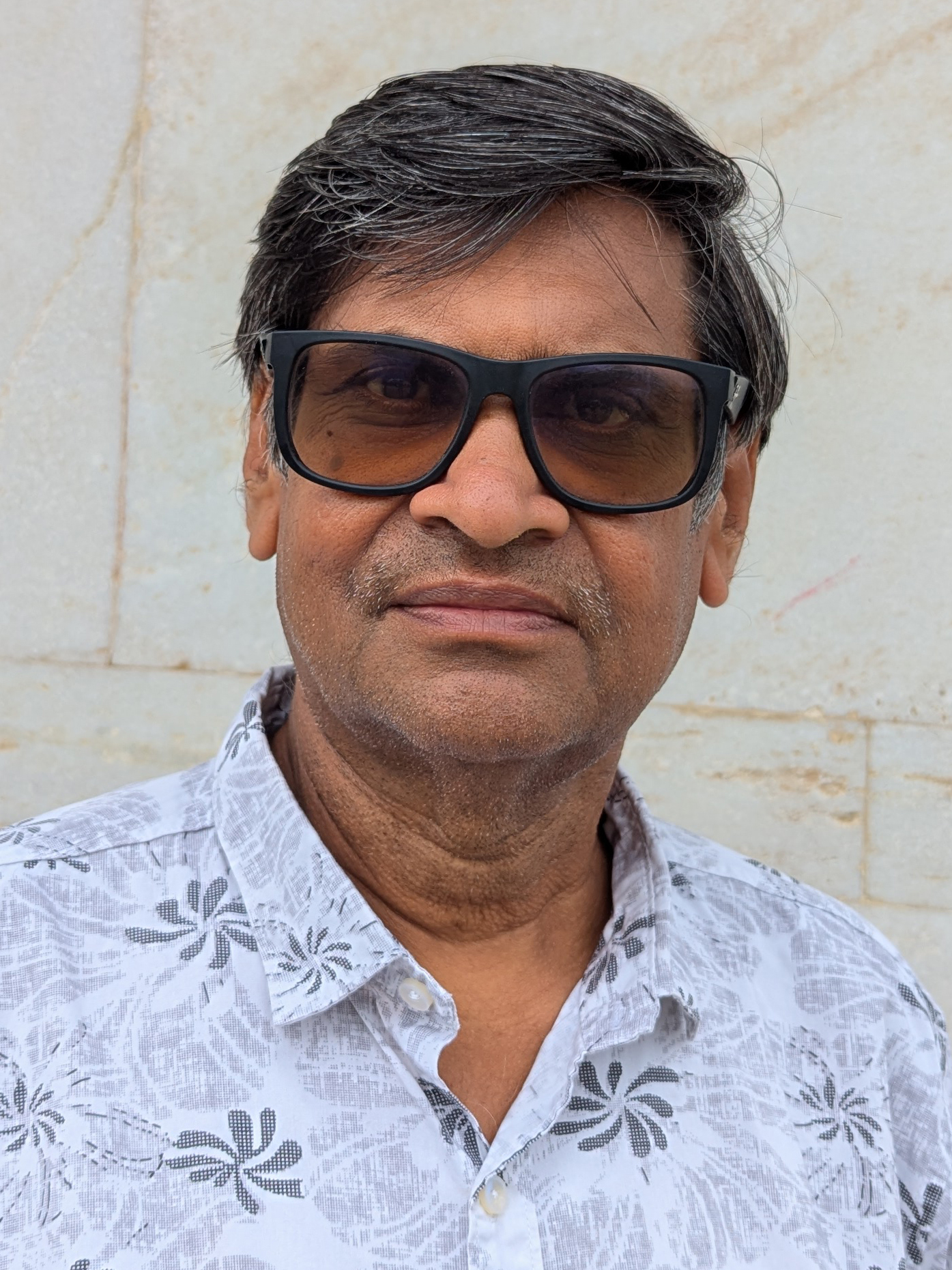

Emmanuel LEROUX

Dassault Systèmes

Emmanuel Leroux is leading the EDA (Electronic Design Automation) strategy for the Simulation Brand (SIMULIA) at Dassault Systèmes. His job, with his Team, is to propose R&D, Partnership to meet a 3Y/6Ytarget for Multi-domain / Multi-scale MODeling and SIMulation (MODSIM) in Electronics involving also manufacturing process simulation. His responsibility includes also more tactical steps and guidance of Go-To-Market and Marketing for the simulation of Semiconductors and PCB (Printed Circuit Boards). Emmanuel received his Ph.D in Electronics in 1998 at University of Lille in France working together with Politecnico di Torino in Italy. In 1994, he joined High Design Technology (Torino) as a PCB Signal Integrity Applications Engineer. In 2020 he joined Computer Simulation Technology (CST), first as Application Engineer (Darmstadt, Germany) and then opening the CST office in Italy. From 2005 he was CST Country Manager for the Southern East Mediterranean area. After the acquisition of CST by Dassault Systèmes in 2016, he led the multi-domain simulation technical/sales Team in that same area. In 2021, he joined Dassault Systèmes SOLIDWORKS Team with the responsibility to launch the Electromagnetic simulation business within SOLIDWORKS resellers at Worldwide level. With his new position Emmanuel has the ambition to plug in EDA MODSIM into a PLM/MBSE/Generative AI framework.

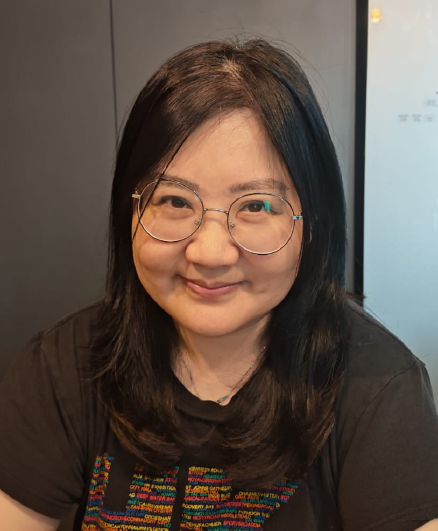

Morteza MOHSENI

Dassault Systèmes

Morteza Mohseni works at Dassault Systèmes SIMULIA as a Roles Portfolio Manager, where he coordinates and contributes to R&D, go-to-market strategy, marketing, and partnership activities to engineer and evolve the SIMULIA brand portfolio within Dassault Systèmes. In this role, he helps to ensure tailored value delivery for semiconductor customers and communities by leveraging market intelligence, close customer engagement, and strategic collaborations. His work supports SIMULIA’s growth objectives, with a particular focus on High-Tech industries and applications in the electronics domain, primarily semiconductors.

He received his PhD from TU Kaiserslautern, Germany, where he worked on the design, simulation, fabrication, and characterization of spintronic-based RF integrated circuits (ICs) and magnetic memories for data processing and data storage systems. He has co-authored more than 30 publications in peer-reviewed journals in the fields of device and applied physics. After a short period of research focused on hardware design for hybrid semiconductor devices for data processing and quantum computing, he transitioned into industry, joining Dassault Systèmes to bridge advanced research with industrial simulation and design workflows.