Simulation Standard

Technical Journal

A Journal for Process and Device Engineers

Electrical Simulation of Liquid Crystals

Liquid Crystals (LCs) are state of matter intermediate between that of a crystalline and a liquid. The optical, mechanical, electrical and magnetic properties of LC medium are defined by the orientation order of the constituent anisotropic molecules. Due to the anisotropy of the electrical properties, the orientation of the LC molecules is effectively controlled by electric fields. As a result, LCs exhibit very specific electrooptical phenomena because of their large birefringence. All of these are important to the functional devices based on LCs, for example, flat panel displays that have been commercialized for decades.

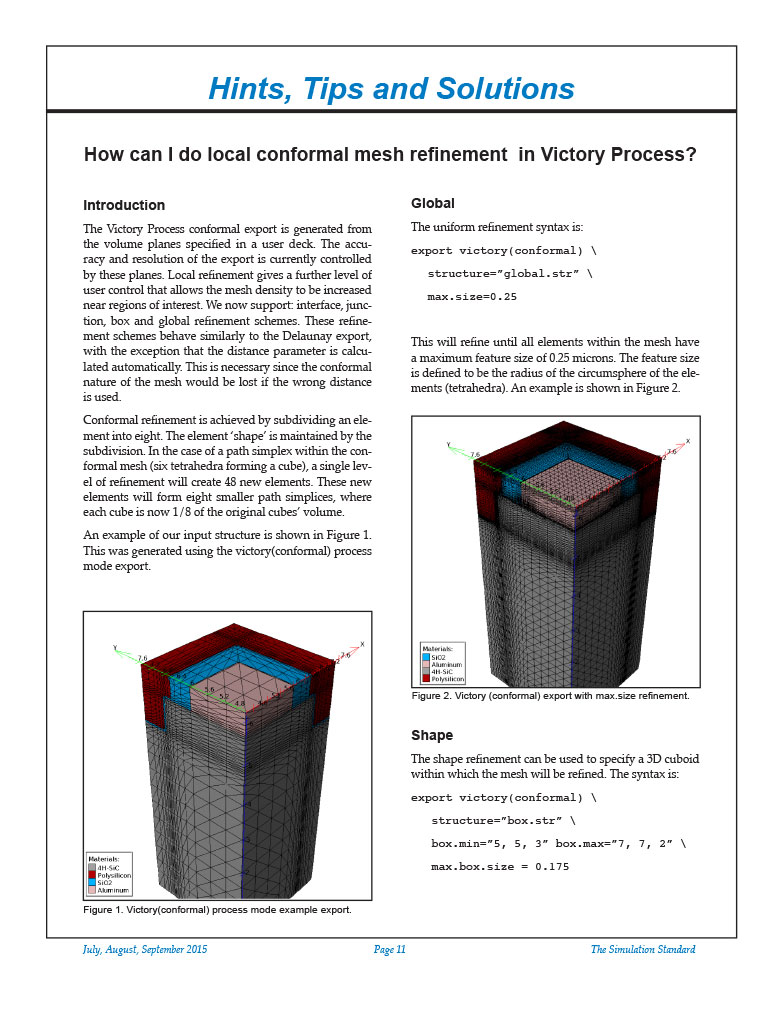

Hints, Tips and Solutions – Local conformal mesh refinement in Victory Process

The Victory Process conformal export is generated from the volume planes specified in a user deck. The accuracy and resolution of the export is currently controlled by these planes. Local refinement gives a further level of user control that allows the mesh density to be increased near regions of interest. We now support: interface, junction, box and global refinement schemes. These refinement schemes behave similarly to the Delaunay export, with the exception that the distance parameter is calculated automatically. This is necessary since the conformal nature of the mesh would be lost if the wrong distance is used.

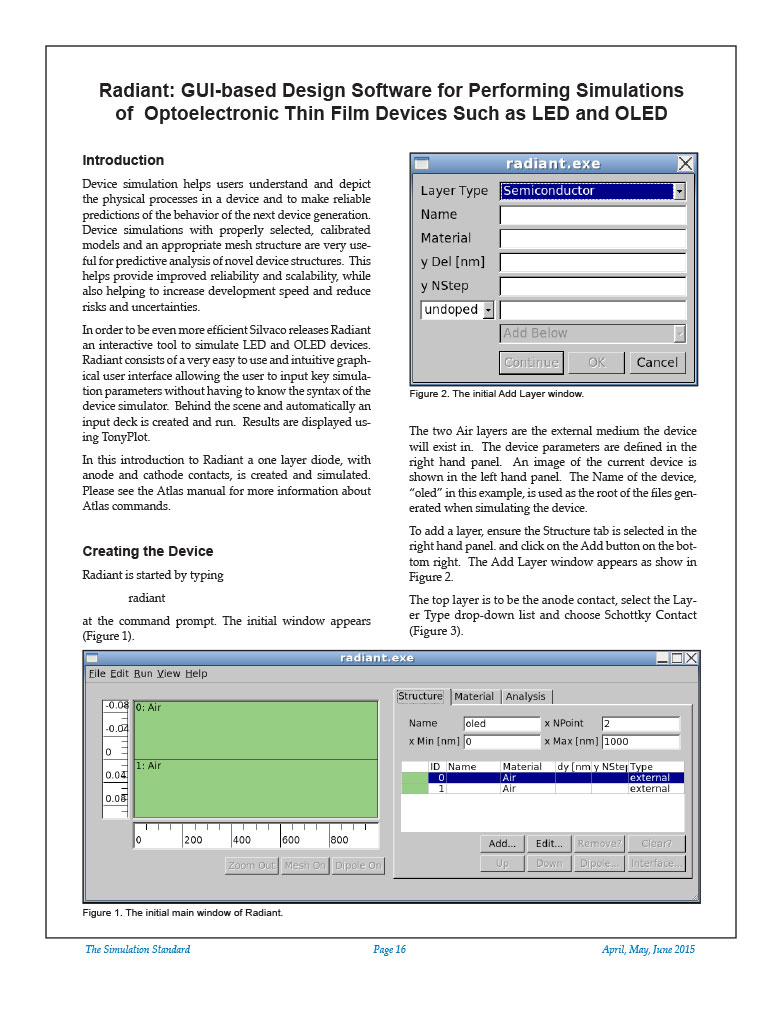

Radiant: GUI-based Design Software for Performing Simulations of Optoelectronic Thin Film Devices Such as LED and OLED

Device simulation helps users understand and depict the physical processes in a device and to make reliable predictions of the behavior of the next device generation. Device simulations with properly selected, calibrated models and an appropriate mesh structure are very useful for predictive analysis of novel device structures. This helps provide improved reliability and scalability, while also helping to increase development speed and reduce risks and uncertainties.

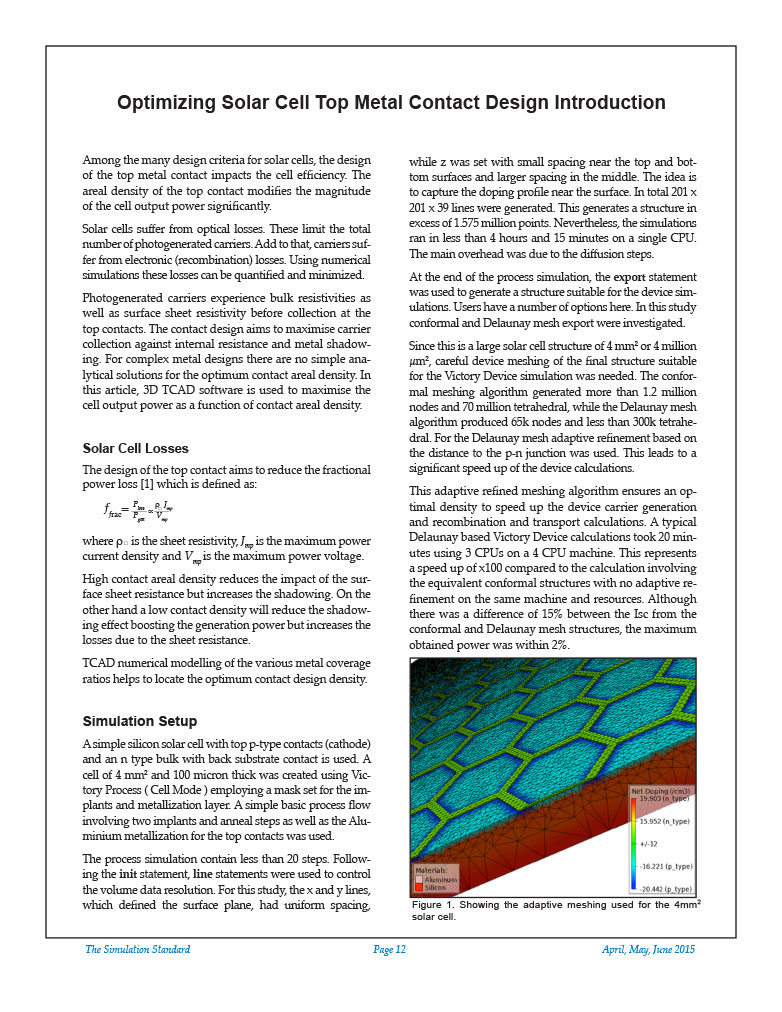

Optimizing Solar Cell Top Metal Contact Design Introduction

Among the many design criteria for solar cells, the design of the top metal contact impacts the cell efficiency. The areal density of the top contact modifies the magnitude of the cell output power significantly.

Vertical LOCOS Power Devices in Victory Process: From 3D Process and Electrical Optimisation to High Speed, Full Chip Process Emulation

There is a constant demand to lower the on-state resistance of devices, improving their energy efficiency as well as increasing their current handling capabilities whilst maintaining the desired breakdown voltage. However, a trade-off relationship exists between the on-state resistance and breakdown voltage. This is referred to as the silicon limit [1]. Attempts have been made to break the silicon limit. One such method proposed by several authors is the Vertical LOCOS MOS (VLOCOS) [2,3].

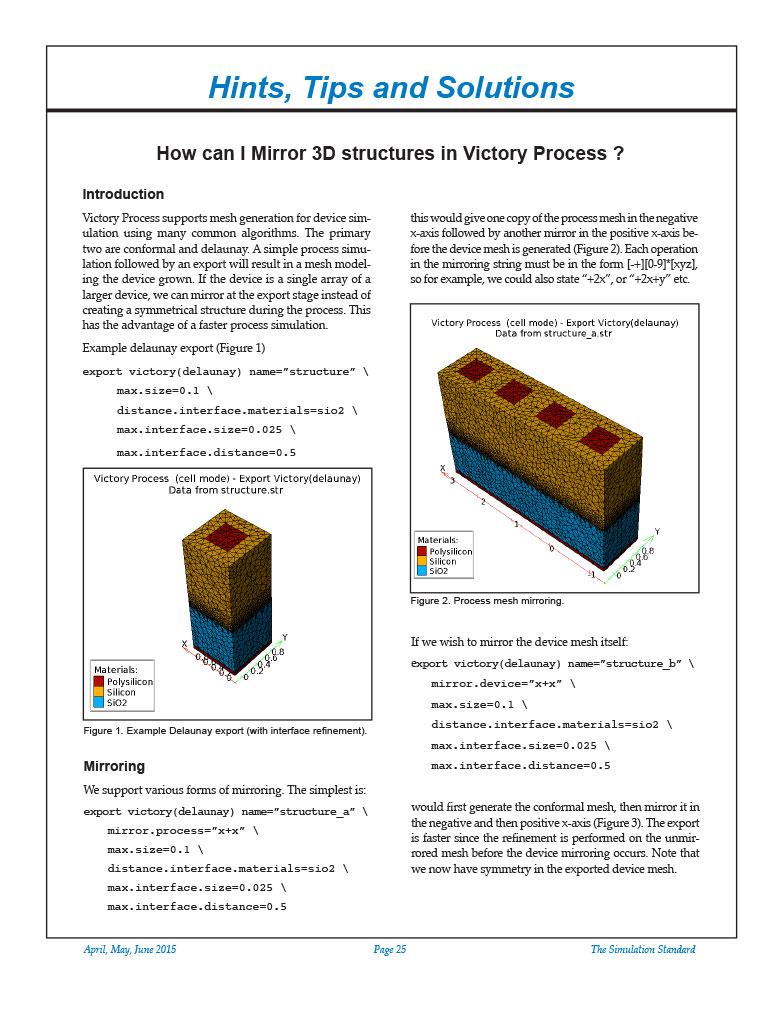

Hints, Tips and Solutions – Mirror 3D structures in Victory Process

Victory Process supports mesh generation for device simulation using many common algorithms. The primary two are conformal and delaunay. A simple process simulation followed by an export will result in a mesh modeling the device grown. If the device is a single array of a larger device, we can mirror at the export stage instead of creating a symmetrical structure during the process. This has the advantage of a faster process simulation.