Simulation Standard

Technical Journal

A Journal for Process and Device Engineers

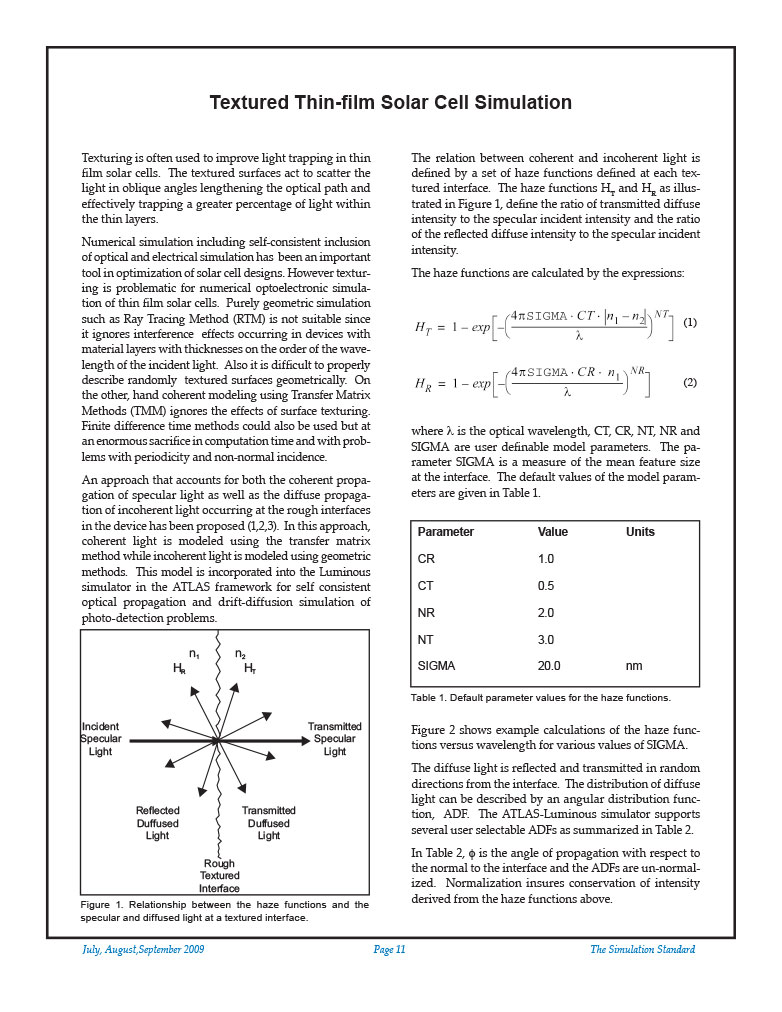

Textured Thin-film Solar Cell Simulation

Texturing is often used to improve light trapping in thin film solar cells. The textured surfaces act to scatter the light in oblique angles lengthening the optical path and effectively trapping a greater percentage of light within the thin layers.

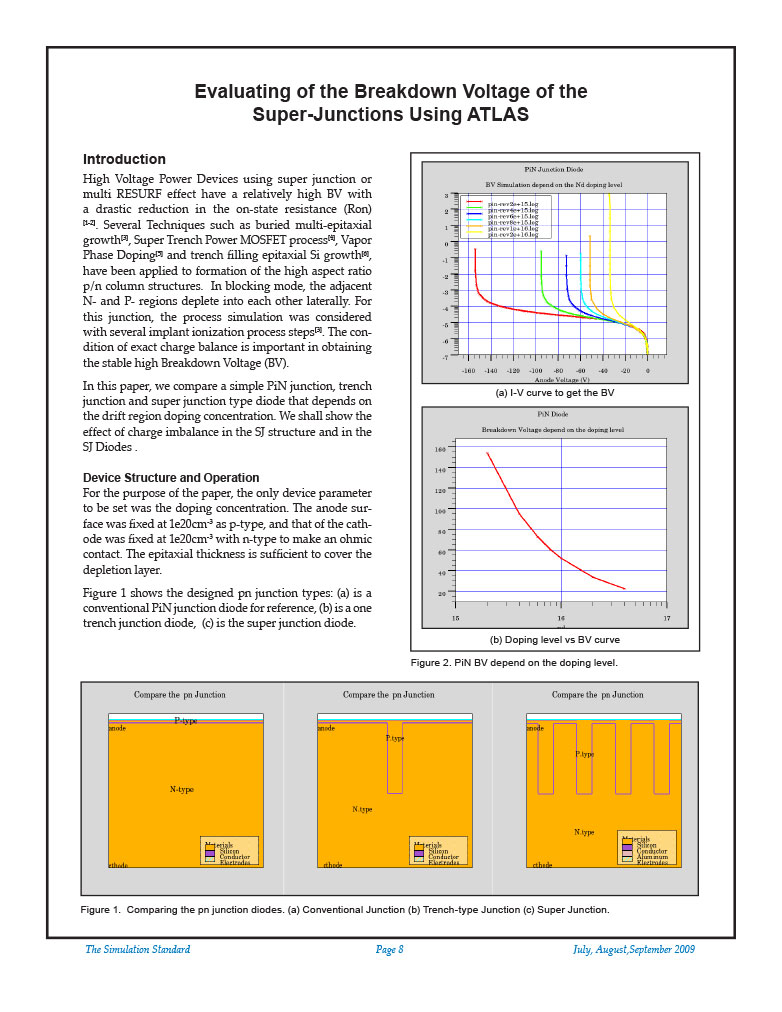

Evaluating of the Breakdown Voltage of the Super-Junctions Using ATLAS

High Voltage Power Devices using super junction or multi RESURF effect have a relatively high BV with a drastic reduction in the on-state resistance (Ron)[1-2]. Several Techniques such as buried multi-epitaxial growth[3], Super Trench Power MOSFET process[4], Vapor Phase Doping[5] and trench filling epitaxial Si growth[6], have been applied to formation of the high aspect ratio p/n column structures. In blocking mode, the adjacent N- and P- regions deplete into each other laterally. For this junction, the process simulation was considered with several implant ionization process steps[3]. The condition of exact charge balance is important in obtaining the stable high Breakdown Voltage (BV).

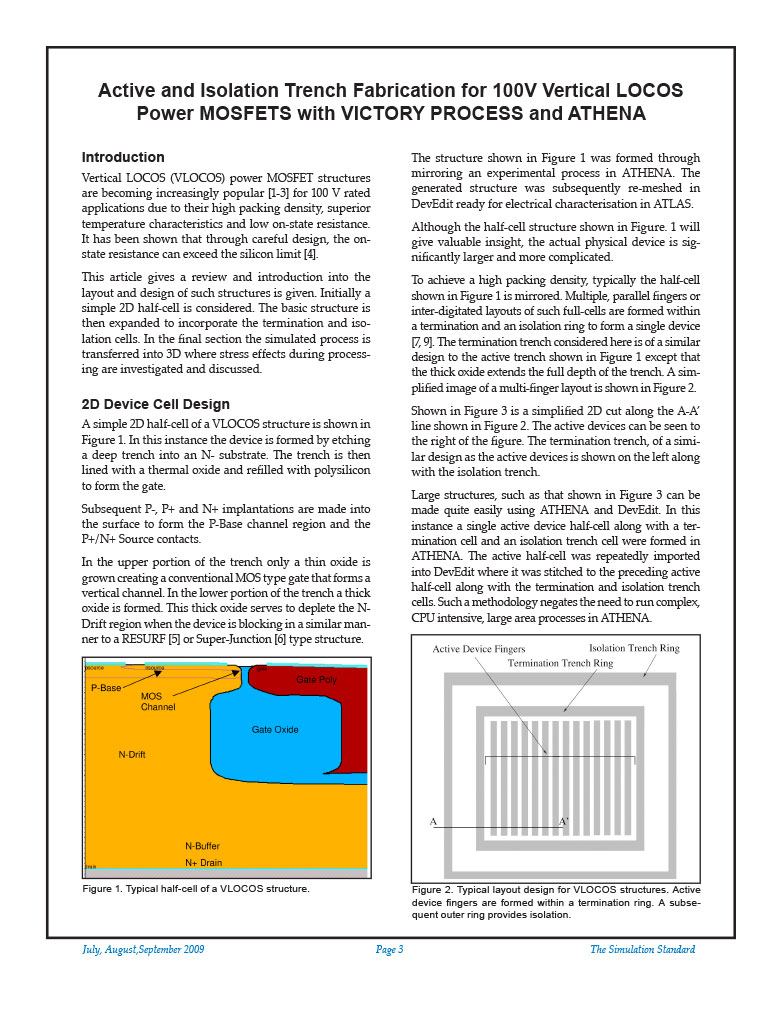

Active and Isolation Trench Fabrication for 100V Vertical LOCOS Power MOSFETS with VICTORY PROCESS and ATHENA

Vertical LOCOS (VLOCOS) power MOSFET structures are becoming increasingly popular [1-3] for 100 V rated applications due to their high packing density, superior temperature characteristics and low on-state resistance. It has been shown that through careful design, the on-state resistance can exceed the silicon limit [4].

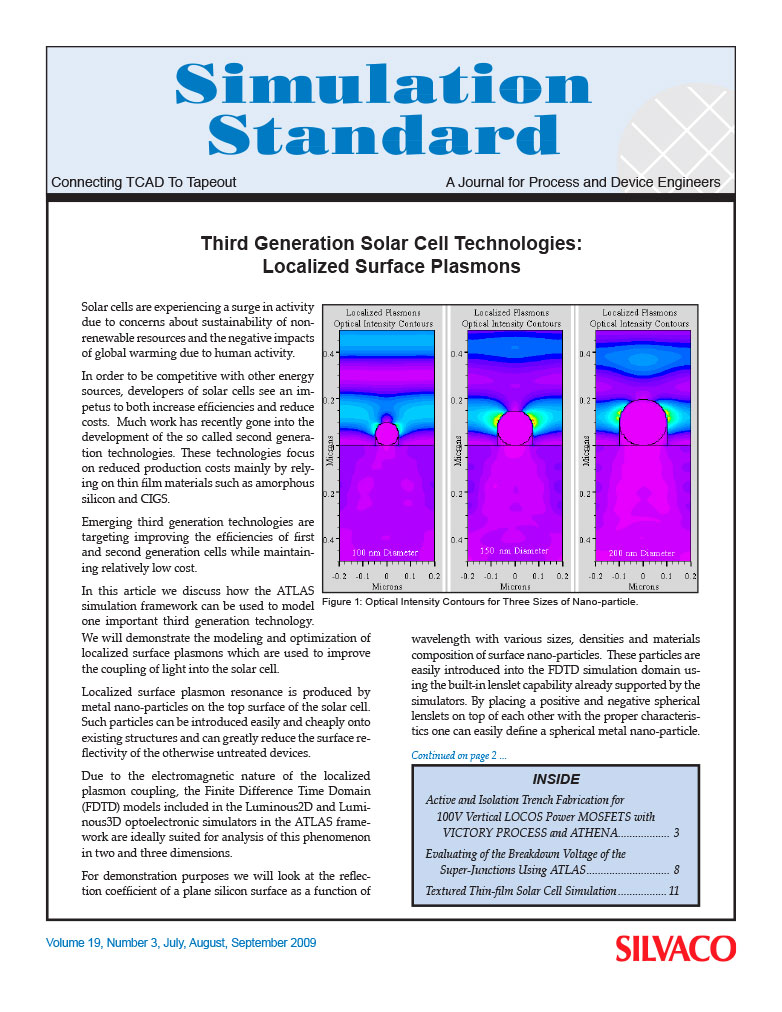

Third Generation Solar Cell Technologies: Localized Surface Plasmons

Solar cells are experiencing a surge in activity due to concerns about sustainability of non-renewable resources and the negative impacts of global warming due to human activity.

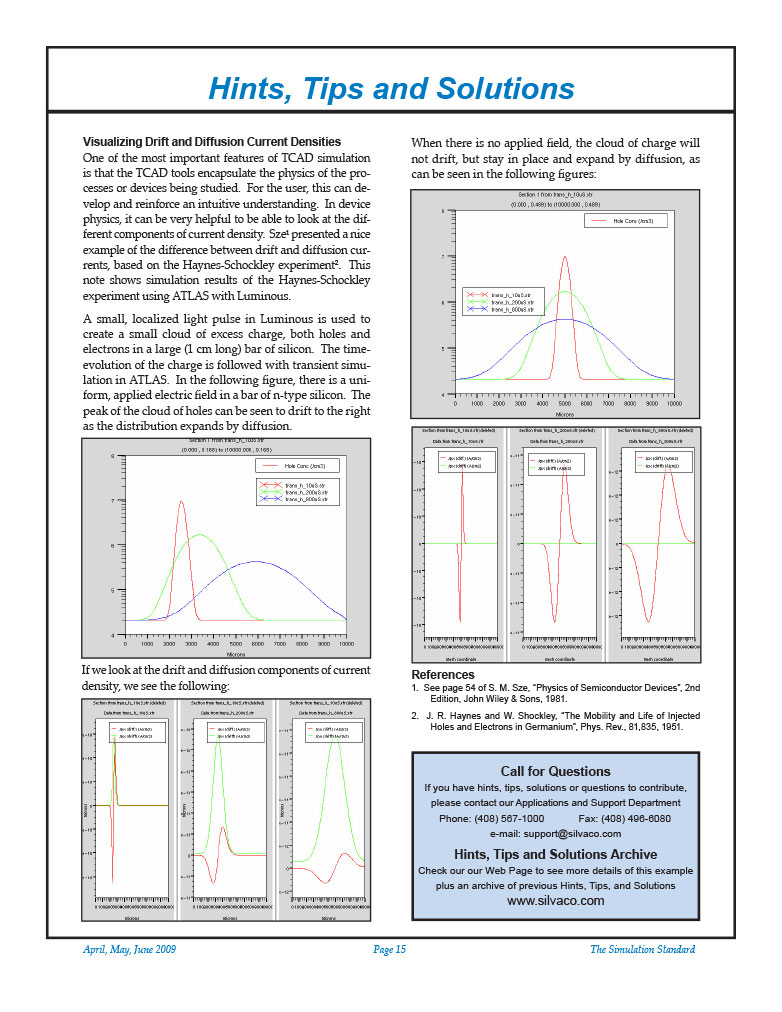

Hints, Tips and Solutions – Visualizing Drift and Diffusion Current Densities

One of the most important features of TCAD simulation is that the TCAD tools encapsulate the physics of the processes or devices being studied. For the user, this can develop and reinforce an intuitive understanding. In device physics, it can be very helpful to be able to look at the different components of current density. Sze1 presented a nice example of the difference between drift and diffusion currents, based on the Haynes-Schockley experiment2. This note shows simulation results of the Haynes-Schockley experiment using ATLAS with Luminous.

Simulating SiGe and Impurity Dependent Stress

The simulation of stress during device fabrication is becoming increasingly important and is often now deliberately introduced during fabrication to enhance device performance. The induced stress can take the form of deposited amorphous materials, such as silicon nitride or can be induced epitaxially by the growth of silicon germanium (SiGe) for example.