Simulation Standard

Technical Journal

A Journal for Process and Device Engineers

Hints, Tips and Solutions – Compare the Results of Breakdown Simulations with Hatakeyama’s Impact Ionization Model for 4H-SiC Based Power Devices

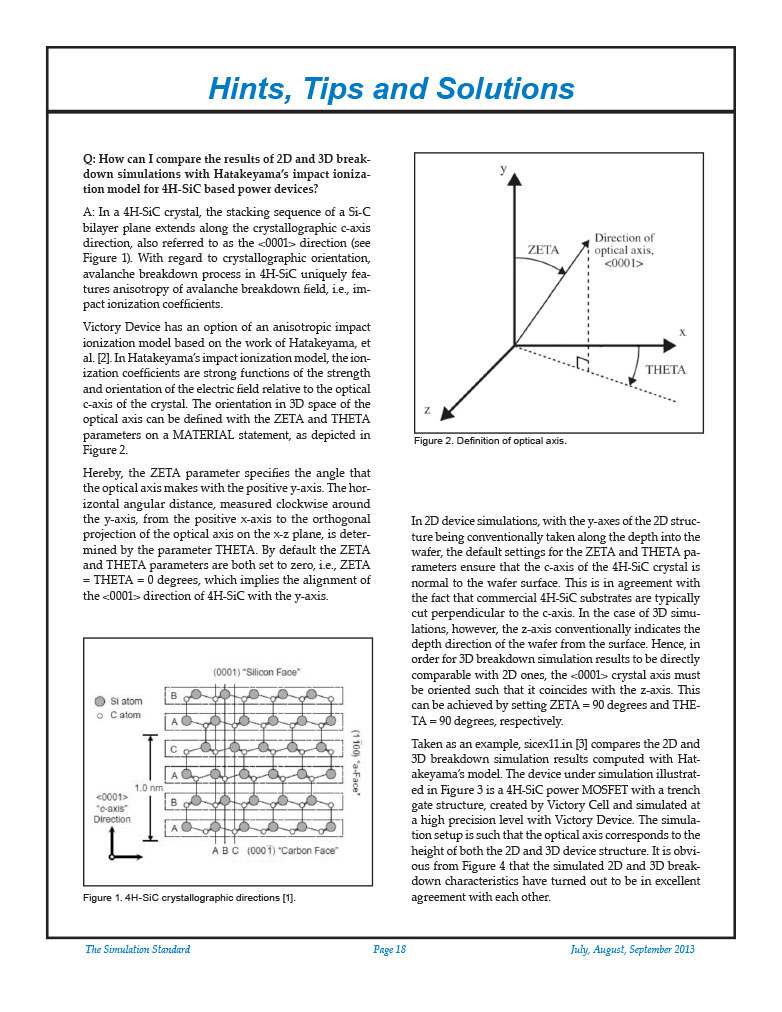

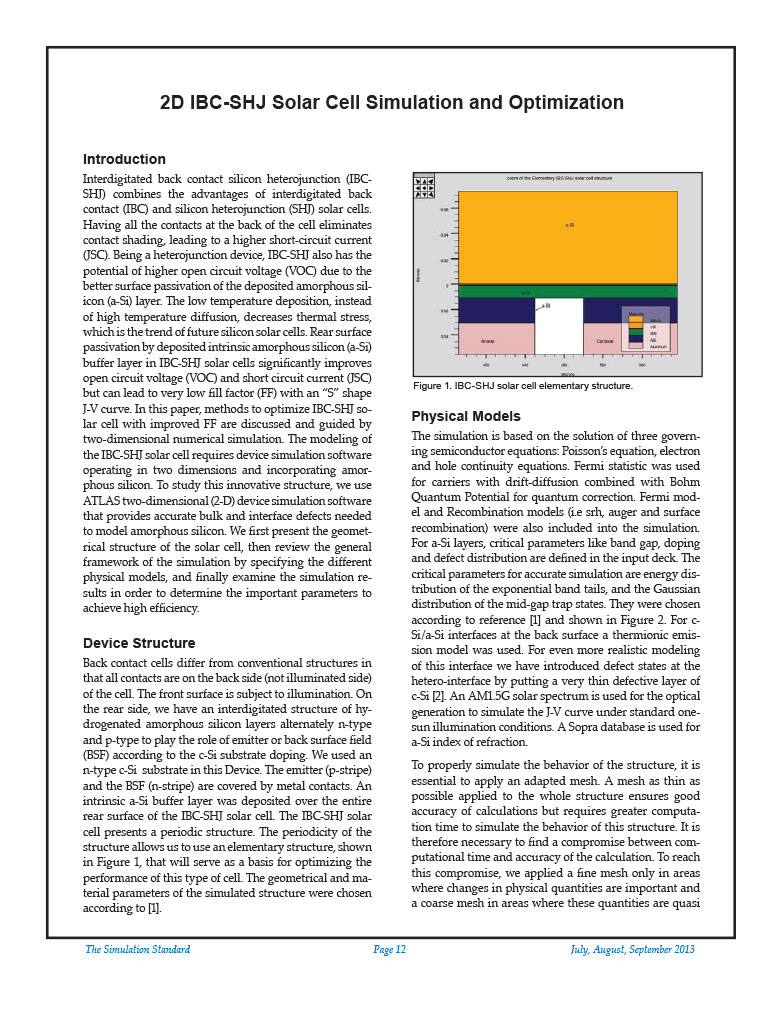

In a 4H-SiC crystal, the stacking sequence of a Si-C bilayer plane extends along the crystallographic c-axis direction, also referred to as the <0001> direction (see Figure 1). With regard to crystallographic orientation, avalanche breakdown process in 4H-SiC uniquely features anisotropy of avalanche breakdown field, i.e., impact ionization coefficients.

2D IBC-SHJ Solar Cell Simulation and Optimization

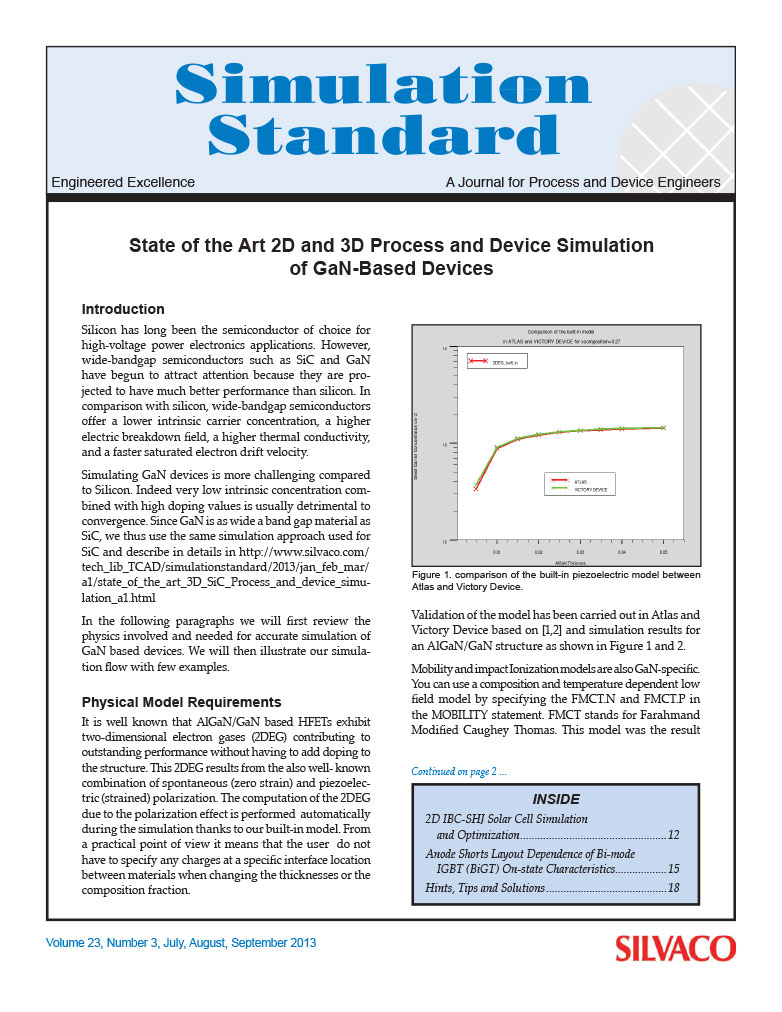

Interdigitated back contact silicon heterojunction (IBC-SHJ) combines the advantages of interdigitated back contact (IBC) and silicon heterojunction (SHJ) solar cells. Having all the contacts at the back of the cell eliminates contact shading, leading to a higher short-circuit current (JSC). Being a heterojunction device, IBC-SHJ also has the potential of higher open circuit voltage (VOC) due to the better surface passivation of the deposited amorphous silicon (a-Si) layer. The low temperature deposition, instead of high temperature diffusion, decreases thermal stress, which is the trend of future silicon solar cells. Rear surface passivation by deposited intrinsic amorphous silicon (a-Si) buffer layer in IBC-SHJ solar cells significantly improves open circuit voltage (VOC) and short circuit current (JSC) but can lead to very low fill factor (FF) with an “S” shape J-V curve. In this paper, methods to optimize IBC-SHJ solar cell with improved FF are discussed and guided by two-dimensional numerical simulation. The modeling of the IBC-SHJ solar cell requires device simulation software operating in two dimensions and incorporating amorphous silicon. To study this innovative structure, we use ATLAS two-dimensional (2-D) device simulation software that provides accurate bulk and interface defects needed to model amorphous silicon. We first present the geometrical structure of the solar cell, then review the general framework of the simulation by specifying the different physical models, and finally examine the simulation results in order to determine the important parameters to achieve high efficiency.

State of the Art 2D and 3D Process and Device Simulation of GaN-Based Devices

Silicon has long been the semiconductor of choice for high-voltage power electronics applications. However, wide-bandgap semiconductors such as SiC and GaN have begun to attract attention because they are projected to have much better performance than silicon. In comparison with silicon, wide-bandgap semiconductors offer a lower intrinsic carrier concentration, a higher electric breakdown field, a higher thermal conductivity, and a faster saturated electron drift velocity.

Hints, Tips and Solutions – Setup Athena Monte Carlo Simulation of Ion Implantation in Silicon Carbide

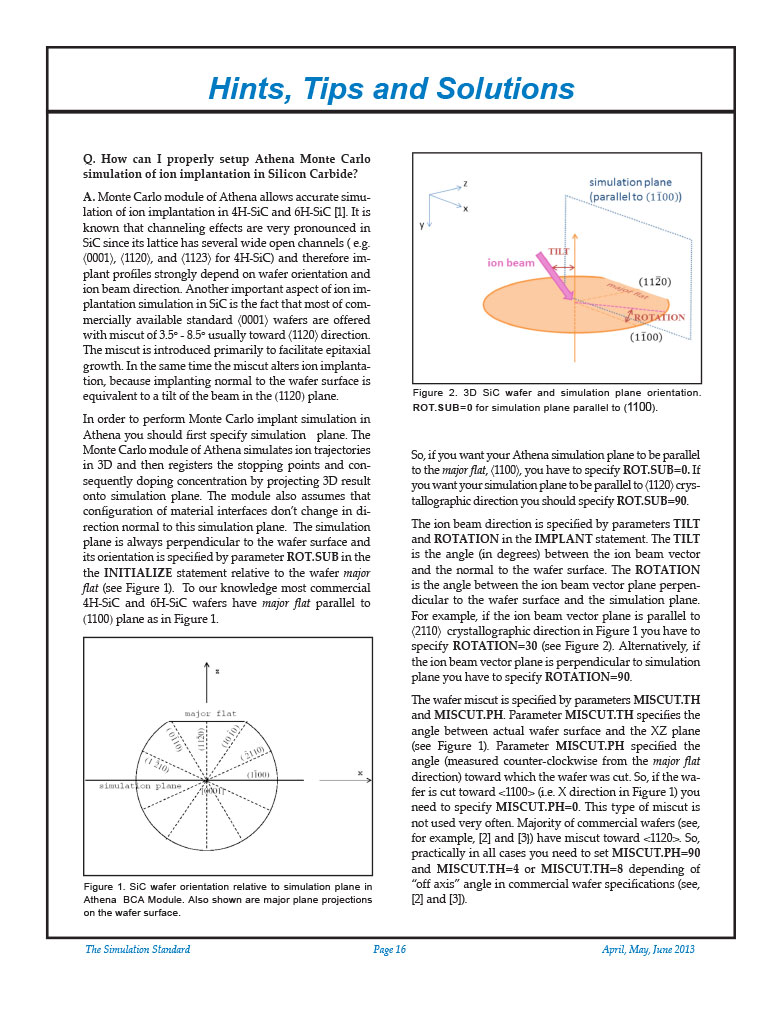

Monte Carlo module of Athena allows accurate simulation of ion implantation in 4H-SiC and 6H-SiC [1]. It is known that channeling effects are very pronounced in SiC since its lattice has several wide open channels ( e.g. 〈0001〉, 〈1120〉, and 〈1123〉 for 4H-SiC) and therefore implant profiles strongly depend on wafer orientation and ion beam direction. Another important aspect of ion implantation simulation in SiC is the fact that most of commercially available standard 〈0001〉 wafers are offered with miscut of 3.5° - 8.5° usually toward 〈1120〉 direction. The miscut is introduced primarily to facilitate epitaxial growth. In the same time the miscut alters ion implantation, because implanting normal to the wafer surface is equivalent to a tilt of the beam in the (1120) plane.

TCAD Simulation of Multiple Quantum Well Infrared Photodetector (QWIP)

We demonstrate the capabilities of SILVACO TCAD tools for the design and simulation of intersubband GaAs/AlGaAs multiple quantum well infrared photodetectors. We compute the photoconductive gain spectrum of the device self consistently with the charge flow, non-radiative capture-escape, and intersubband transitions in the active region. The solid state calculations provide input to a light propagation modeling tool that allows for multiple reflections in the layered geometry of the active region. From this full calculation, we extract light absorption and quantum efficiency as a function of the angle of incidence and the wavelength of a mono-spectral beam of light. This TCAD simulation can be used as a starting point by design engineers for obtaining guide lines to analyze and optimize quantum well infrared photodetectors.

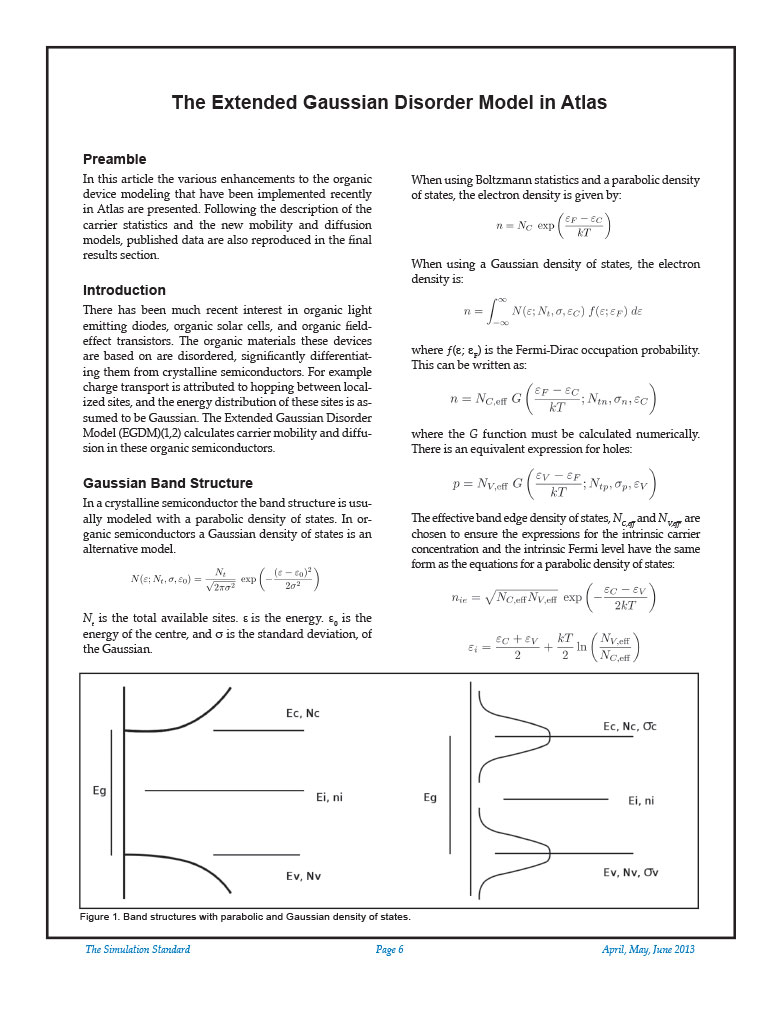

The Extended Gaussian Disorder Model in Atlas

In this article the various enhancements to the organic device modeling that have been implemented recently in Atlas are presented. Following the description of the carrier statistics and the new mobility and diffusion models, published data are also reproduced in the final results section.