Simulation Standard

Silvaco面向半导体工艺和器件仿真工程师推出的技术刊物

Maverick: Hierarchical Netlist Extractor for PC Platforms

Diamond is considered to be the ultimate semiconductor material for high power and high frequency devices due to its superior electrical and thermal properties, such as high breakdown field, high carrier mobility, low dielectric constant, and high thermal conductivity, as shown in Table 1.

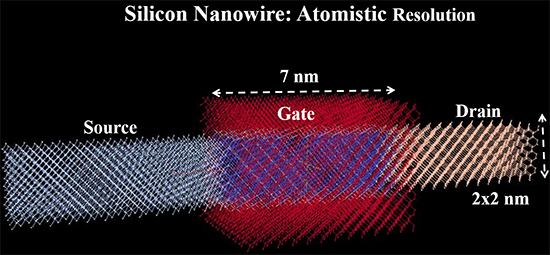

Next Generation CMOS Nanowire: From Atoms to Circuit Simulation

Abstract— A complete simulation flow for a Nanowire-based ring oscillator circuit is presented, where the active devices were simulated using an atomistic device simulator. The results of this simulation have been fitted to an active device SPICE compact model, specifically formulated for nanowire/Gate all around Field Effect Transistors” (FETs). Finally, the active devices were incorporated into a SPICE netlist including back end resistance and capacitance parasitics.

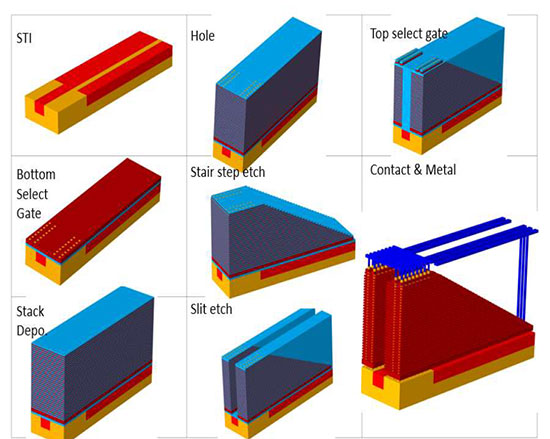

Optimization of Select Gate Transistor in Advanced 3D NAND Memory Cell

Abstract—There are several device challenges unique to the select gate transistor in 3D NAND memory cell. It requires low leakage current to prevent read and program disturb problems and it needs to provide enough current during read and erase operation. In this paper, we examined the design optimization of select gate transistor with respect to various device elements including work-function, S/D overlap, and trap density. Finally, we reviewed the path to reduce the channel length of the select gate transistor in conjunction with the role of dummy cells.

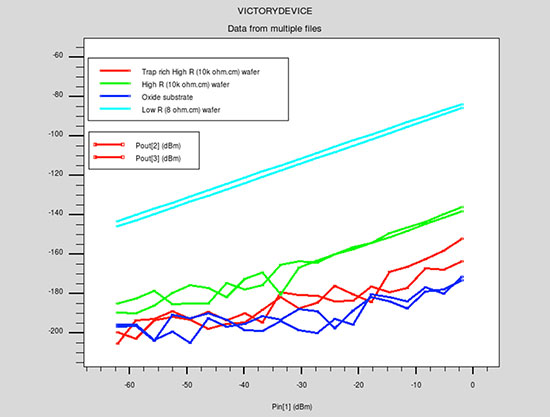

RFSOI Switch Harmonics Simulations with Trap-Rich Substrate

In this paper, in order to understand trap-rich substrate behavior, passive and active device on SOI with trap-rich layer structures were simulated using the Victory Device simulator. Harmonics distortion of devices were also compared.

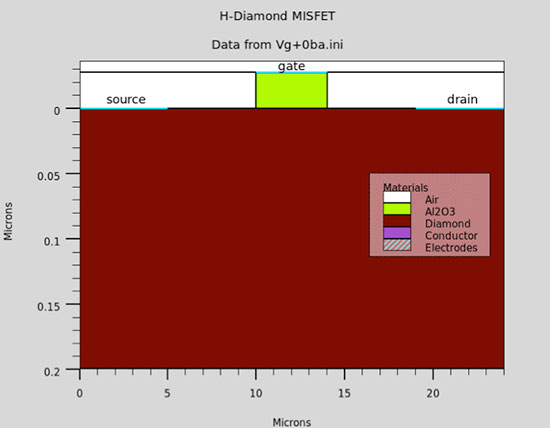

Estimation of Interface Property Changes Between Normally On/Off Hydrogenated Diamond MISFETs

Introduction

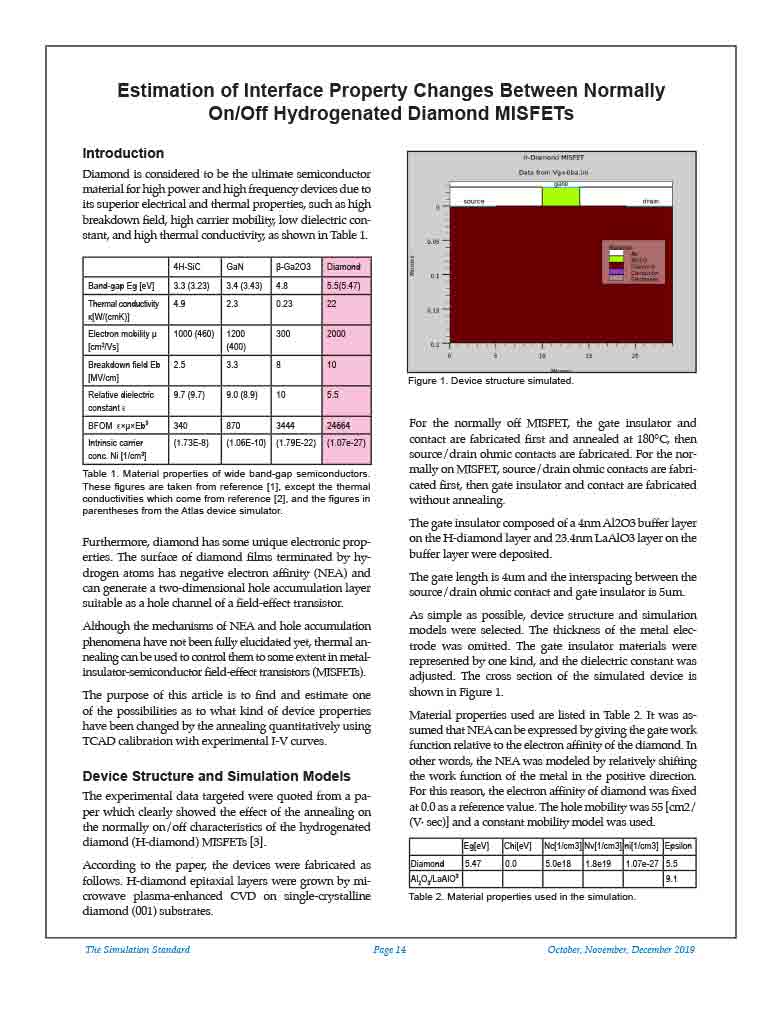

Diamond is considered to be the ultimate semiconductor material for high power and high frequency devices due to its superior electrical and thermal properties, such as high breakdown field, high carrier mobility, low dielectric constant, and high thermal conductivity, as shown in Table 1.

Furthermore, diamond has some unique electronic properties. The surface of diamond films terminated by hydrogen atoms has negative electron affinity (NEA) and can generate a two-dimensional hole accumulation layer suitable as a hole channel of a field-effect transistor.

TCAD Simulation of Electric Field Distribution in Gallium Nitride Trench-based Power Devices

Introduction

Gallium nitride (GaN)-based devices are excellent candidates for high-voltage and high-power applications, due to the superior physical properties of GaN compared to Si, SiC, and GaAs. Recently, GaN vertical devices have attracted increased attention, due to their advantages over GaN lateral devices, including high breakdown voltage (BV) and current capability for a given chip size, and superior thermal performance.1 Recent demonstrations of high-performance vertical GaN diodes2–4 and transistors5–9 have made vertical structures very promising for GaN power devices.