Simulation Standard Technical Journal

A Journal for Process and Device Engineers

Hints, Tips, and Solutions – Simulation on a Cluster of Computers Using the Distributed Computing Feature

A new feature that is introduced in Silvaco’s TCAD applications allows the user to run a parallel simulation on a cluster of computers within a network.

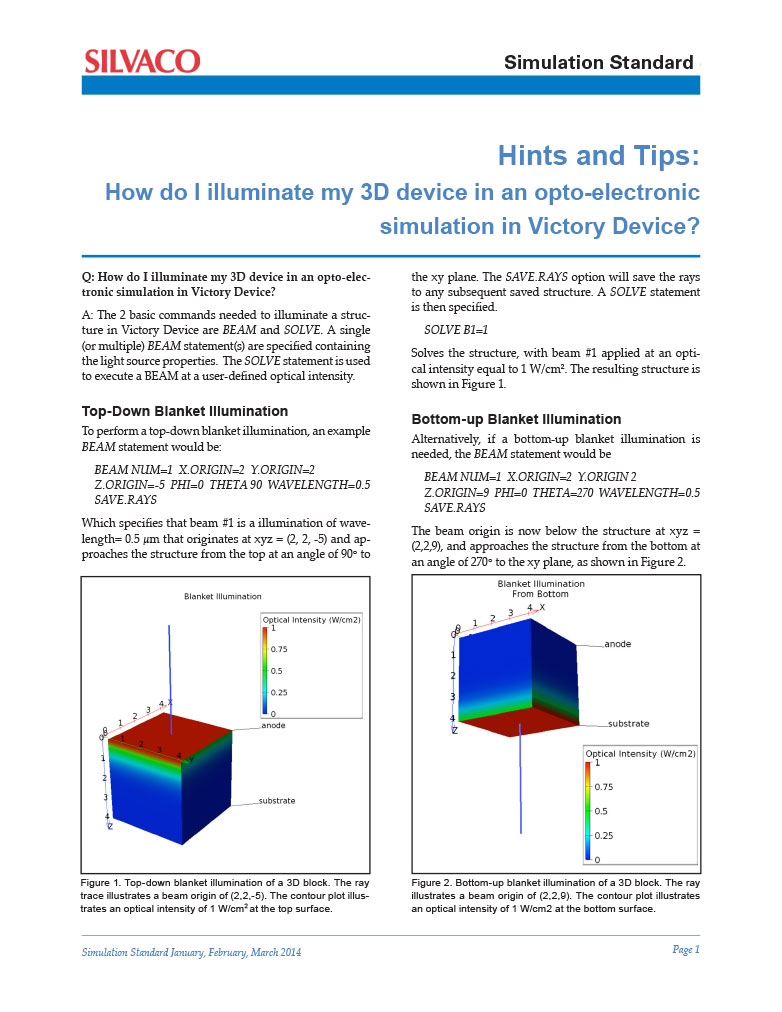

Hints, Tips and Solutions – Illuminate a 3D device in a Victory Device Opto-electronic Simulation

A: The 2 basic commands needed to illuminate a structure in Victory Device are BEAM and SOLVE. A single (or multiple) BEAM statement(s) are specified containing the light source properties. The SOLVE statement is used to execute a BEAM at a user-defined optical intensity.

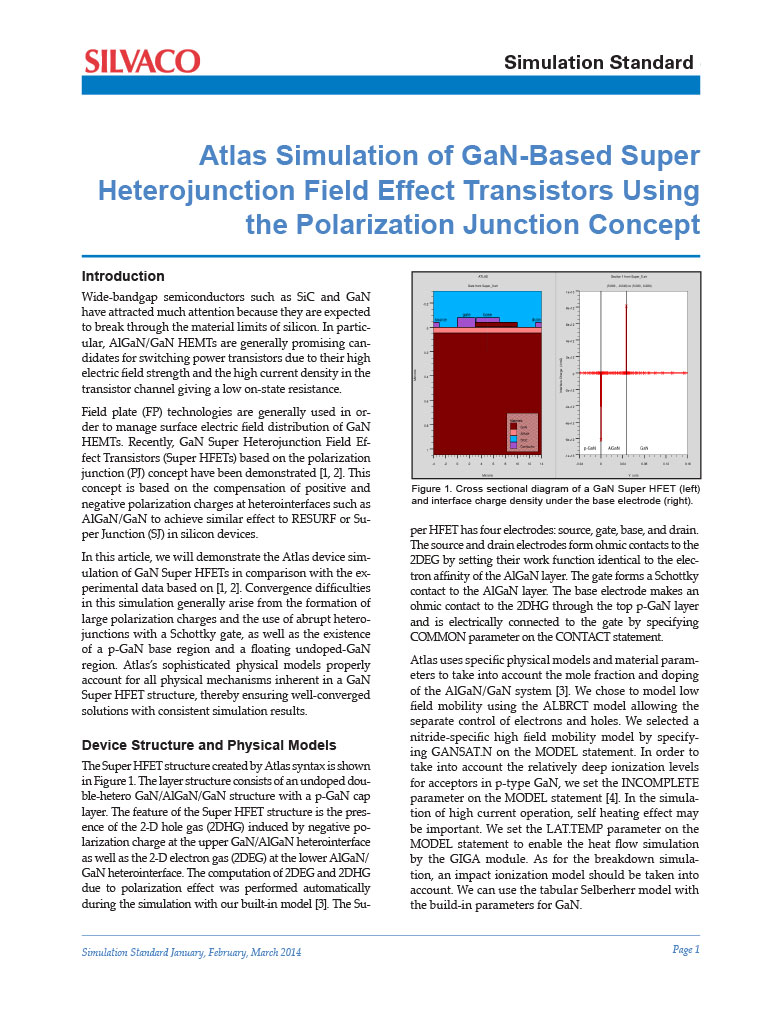

Atlas Simulation of GaN-Based Super Heterojunction Field Effect Transistors Using the Polarization Junction Concept

Wide-bandgap semiconductors such as SiC and GaN have attracted much attention because they are expected to break through the material limits of silicon. In particular, AlGaN/GaN HEMTs are generally promising candidates for switching power transistors due to their high electric field strength and the high current density in the transistor channel giving a low on-state resistance.

Modeling the Optical Response of Phonon-dressed Excitons in OLED Simulations

We demonstrate the modeling of optical response of exciton-polarons based on the well established Holstein Hamiltonian to model coupled exciton-phonon systems in organic molecular chains. Our approach uses Green’s functions to compute the density of states and the linear optical susceptibility, and thus eliminates the conventional and computationally expensive step of diagonalizing a large Hamiltonian matrix. We exploit this technique further to focus exclusively on the optically active states when computing the linear optical response, and significantly reduce the computational effort to construct the optical susceptibility. In this article, we demonstrate the computation of absorption and emission spectra of Alq3 at 4.2 K and at room temperature using our model. Using the two parameters of the Holstein model, the inhomogeneous broadening energies, and a phenomenological reorganization energy of the solute, we obtain excellent fits to established experimental results. We then use this model inside the larger simulation of a 3-layer organic light emitting (OLED) structure composed of Alq3, Alq3:DCJTB, and α-NPD, which are the electron transport, emissive, and hole transport layers respectively. In our methodology, we also couple the optical response into the rate equations for exciton dynamics in addition to computing the spectrum of light output by the device.

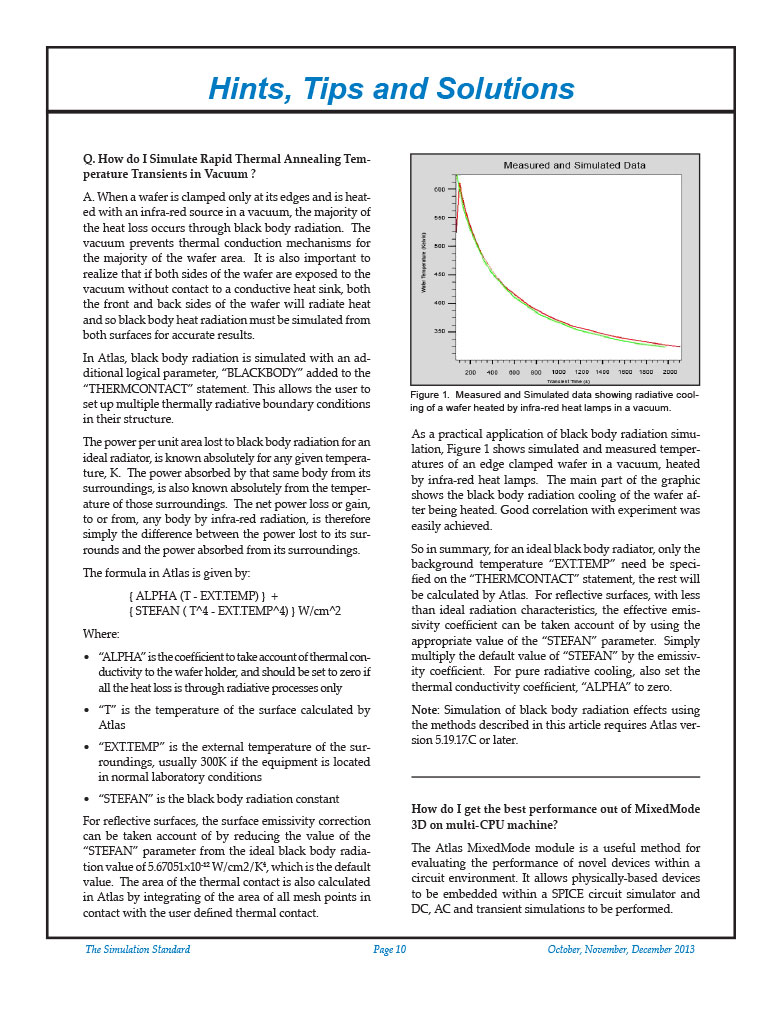

Hints, Tips, and Solutions – Simulate Rapid Thermal Annealing Temperature Transients in Vacuum

When a wafer is clamped only at its edges and is heated with an infra-red source in a vacuum, the majority of the heat loss occurs through black body radiation. The vacuum prevents thermal conduction mechanisms for the majority of the wafer area. It is also important to realize that if both sides of the wafer are exposed to the vacuum without contact to a conductive heat sink, both the front and back sides of the wafer will radiate heat and so black body heat radiation must be simulated from both surfaces for accurate results.

Atlas Simulation of a Wide Bandgap Gallium Oxide (Ga2O3) MOSFET

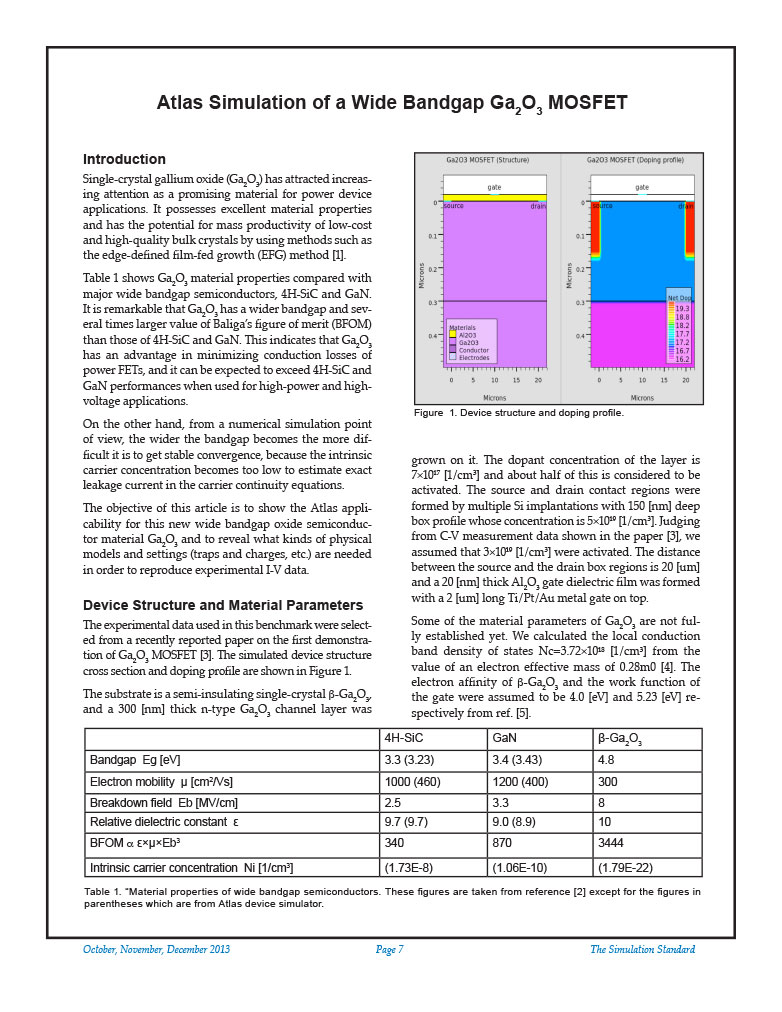

Single-crystal gallium oxide (Ga2O3) has attracted increasing attention as a promising material for power device applications. It possesses excellent material properties and has the potential for mass productivity of low-cost and high-quality bulk crystals by using methods such as the edge-defined film-fed growth (EFG) method [1].