Simulation Standard Technical Journal

A Journal for Process and Device Engineers

Interactive Tools – New Features in 2019 Baseline Release

DeckBuild is Silvaco’s state of the art simulator interface. It is capable of running all simulators from Silvaco as well as many of the visualization tools. Figure 4-1 shows an overview where a simulation was successfully finished and the results can be inspected. Values that were extracted from a structure file are shown in the top right part of the window.

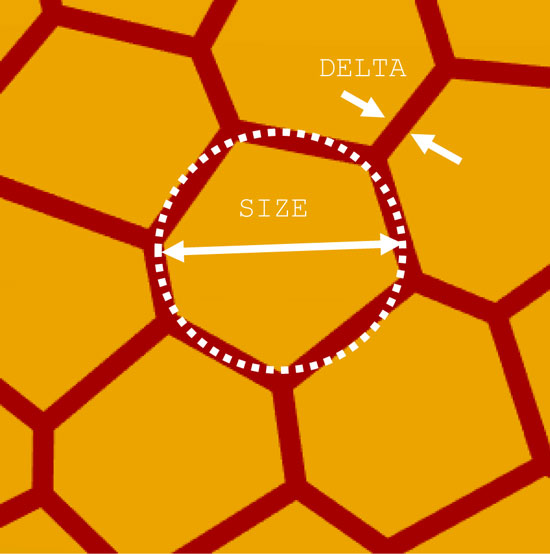

3D TFT Simulation of Grains and Grain Boundaries

Introduction

Low-temperature polycrystalline silicon (LTPS) thin-film transistors have been widely applied to AMOLED (Active Matrix Organic Light Emitting Diode) as the most suitable means for high mobility, high switching speed and high resolution [1-2].

A Laser Annealing Process such as Excimer Laser Annealing (ELA) is used to manufacture by converting Amorphous Silicon (a-Si) to Polycrystalline Silicon (poly-Si) at low temperature. The poly-Si structure (produced through ELA) shows the laser wavelength, pulse width and spatial beam dependencies.

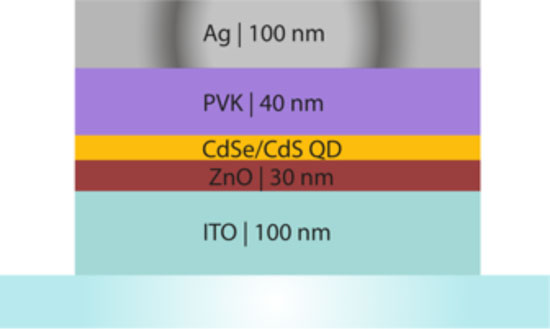

Quantum Dot-Based Hybrid Light Emitting Diode Modelling Using Radiant

Introduction

With the recently launched Radiant, a graphical user interface (GUI) for Atlas-based TCAD simulations, the entry barrier for inexperienced users has been lowered. In particular, the use of guided simulation tools, for both experienced and novice researchers, can speed up the development cycle. Light emitting diodes (LEDs) have caught the attention of the scientific community for many years, especially organic-based light emitting diodes (OLEDs) and the emerging quantum dot-based light emitting diodes (QD-LEDs).

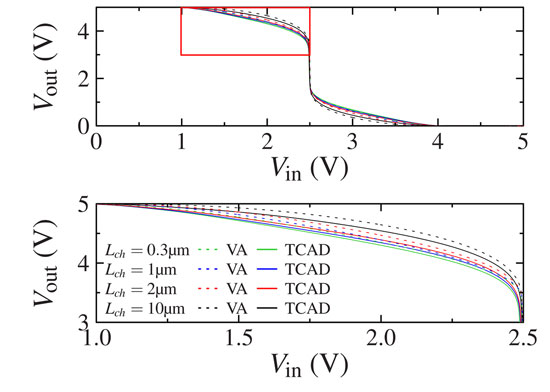

Verification of an Compact Model for Organic Thin-Film-Transistors by Using MixedMode Creating an CMOS Inverter Circuit with TCAD Transistor Devices

Organic thin-film transistors (OTFTs) are promising devices for future low-cost electronics[1][2]. However, to enable the development of this technology, circuit design simulation is needed. TCAD with MixedMode approach provides a suitable route for the physics based simulation of these transistors within simple circuits. As circuits become more complicated, more devices are needed and the computing time increases significantly. Compact models describe the behavior of the device with only a few equations and thus the computing time is reduced to a viable magnitude. Such equations are written down in a Verilog-A format which can be used by most SPICE simulators.

Hints, Tips and Solutions – Movie and PDF Report Generation with the DeckBuild GUI

Introduction

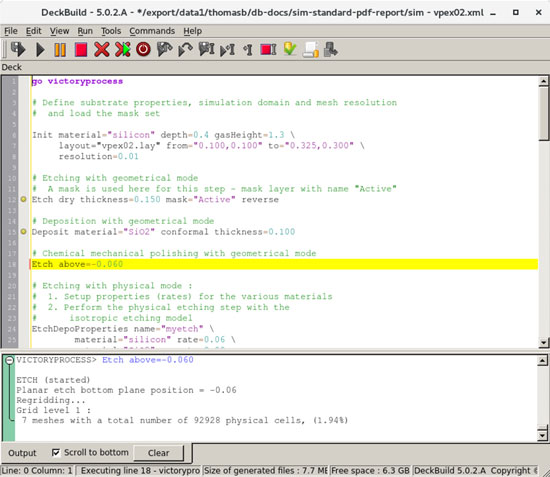

In this article we will emphasize two new features of the DeckBuild deck editing environment. These are the movie creation on the one hand and the creation of PDF reports on the other. The latest version of DeckBuild allows you to use recorded history points to prepare movies and PDF reports of a simulation flow. We will start by first illustrating the basic history creation and script execution mechanism, followed by pointing out the creation of movies. After that, we will demonstrate how to create a customized PDF report out of your simulation flow.

Process Variation, Alignment and BEOL Effects on Circuit Level Performance

As process nodes continue to shrink, the requirement for additional physics is gradually creeping into each stage of the design process. By way of illustration, TCAD simulations are becoming more atomistic in nature, SPICE models are becoming process-aware to take account of localized strain effects, and back or middle end of line (BEOL and MEOL) parasitics are moving from exclusively 2D rule based solutions to full 3D structure field solvers for numerous critical sections of the layout.