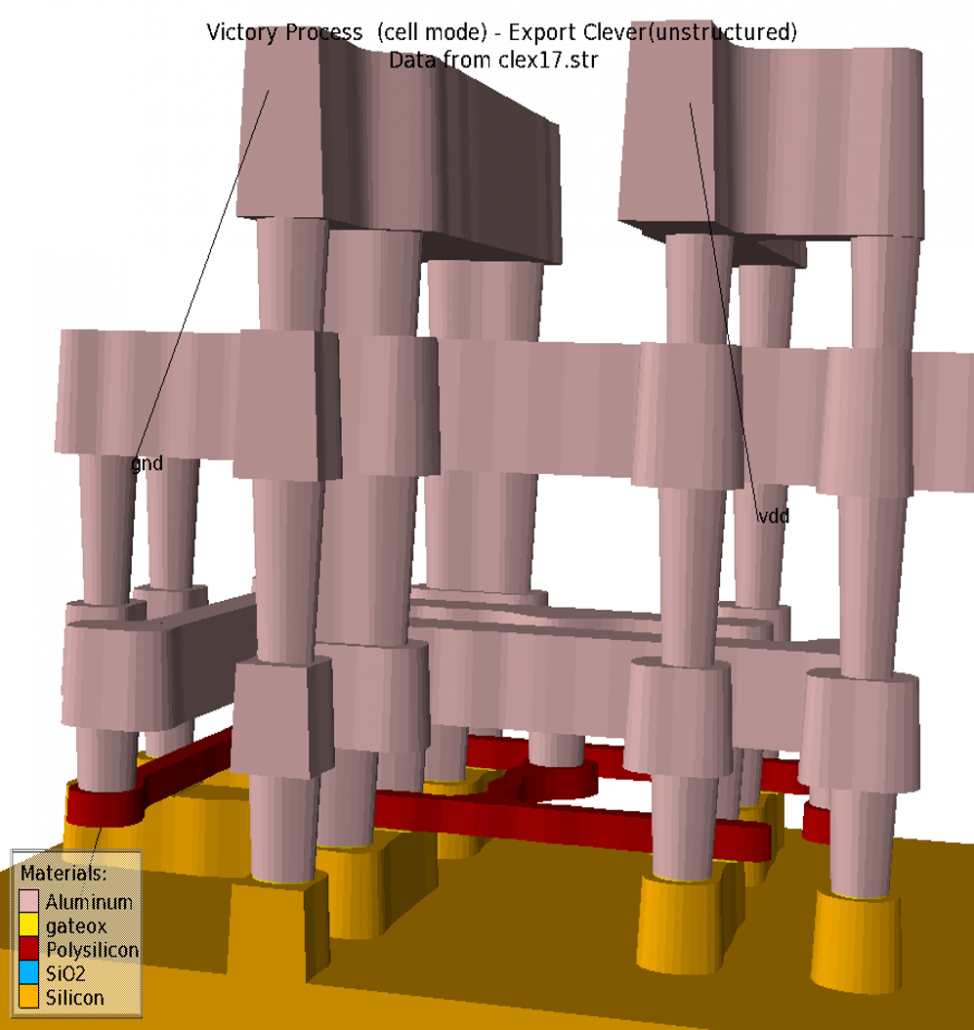

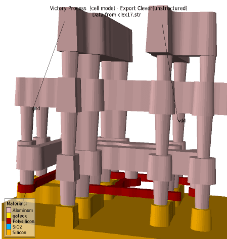

Victory Process 2D and 3D Layout-Driven Simulator

TCAD Process simulation is crucial to develop new technologies, as well as maintain existing semiconductor processes. Virtualizing the manufacturing process allows organizations to maintain a “digital twin” of their semiconductor process. Changes in process can be well understood; maximizing device performance, increase manufacturing yield, while minimizing number of engineering cycles and cycle time.

Benefits

- Allow optimization of existing processes and provides predictive scaling behavior

- Increase understanding of novel technology challenges

- Reduce mask and prototyping foundry cost by replacing experiments by simulation

- Reduce time-to-market by creation of virtual process based PDK prior to silicon for fabless companies

Typical Applications

- Advanced CMOS: FinFET, FDSOI, Bulk CMOS

- Display technology: TFT, LED, OLED

- Power & RF technologies: Silicon BiCMOS and BCD, SiC, GaN

- Optical and photonics: CIS, Solar Cell, Laser, Waveguides, Modulators

How Can I Re-Use Individual Monte-Carlo 3D Implant Profiles?

Comparison of Models for Fluorine Effect on Dopant Diffusion in CMOS Processes

Setting up the Wafer Orientation: Applications to Ion Implantation

Optoelectronic Component Design for Photonic Integrated Circuits