Simulating Selective and Non-Selective Epitaxy over Oxide Isolated Regions Using Athena

1.0 Introduction

In certain cases, most notably in modern bipolar and SiGe HBT structures, epitaxial steps are performed after the oxide isolation structures have been already created. Thus the initial surface prior to epitaxy may contain regions of crystalline silicon, polysilicon or insulators, usually silicon dioxide. In the case of LOCOS isolation, the surface is also non-planar. In such epitaxial cases, epitaxy can be divided into two general types:-

(i) non selective epitaxy

(ii) selective epitaxy

In the first case, silicon is deposited epitaxially onto any exposed crystalline surface, and polysilicon is deposited onto amorphous regions such as oxide isolation or regions where poly-silicon already exists.

In the second case, the use of selective chemistry increases the silicon layer seeding time on non crystalline surfaces to such an extent, that effectively silicon is only deposited epitaxially onto exposed crystalline surfaces. No polysilicon or amorphous silicon is deposited onto the oxide isolated regions.

In this article, the methodology for simulating both these scenarios is described.

2.0 Non Planar LOCOS Structure Example

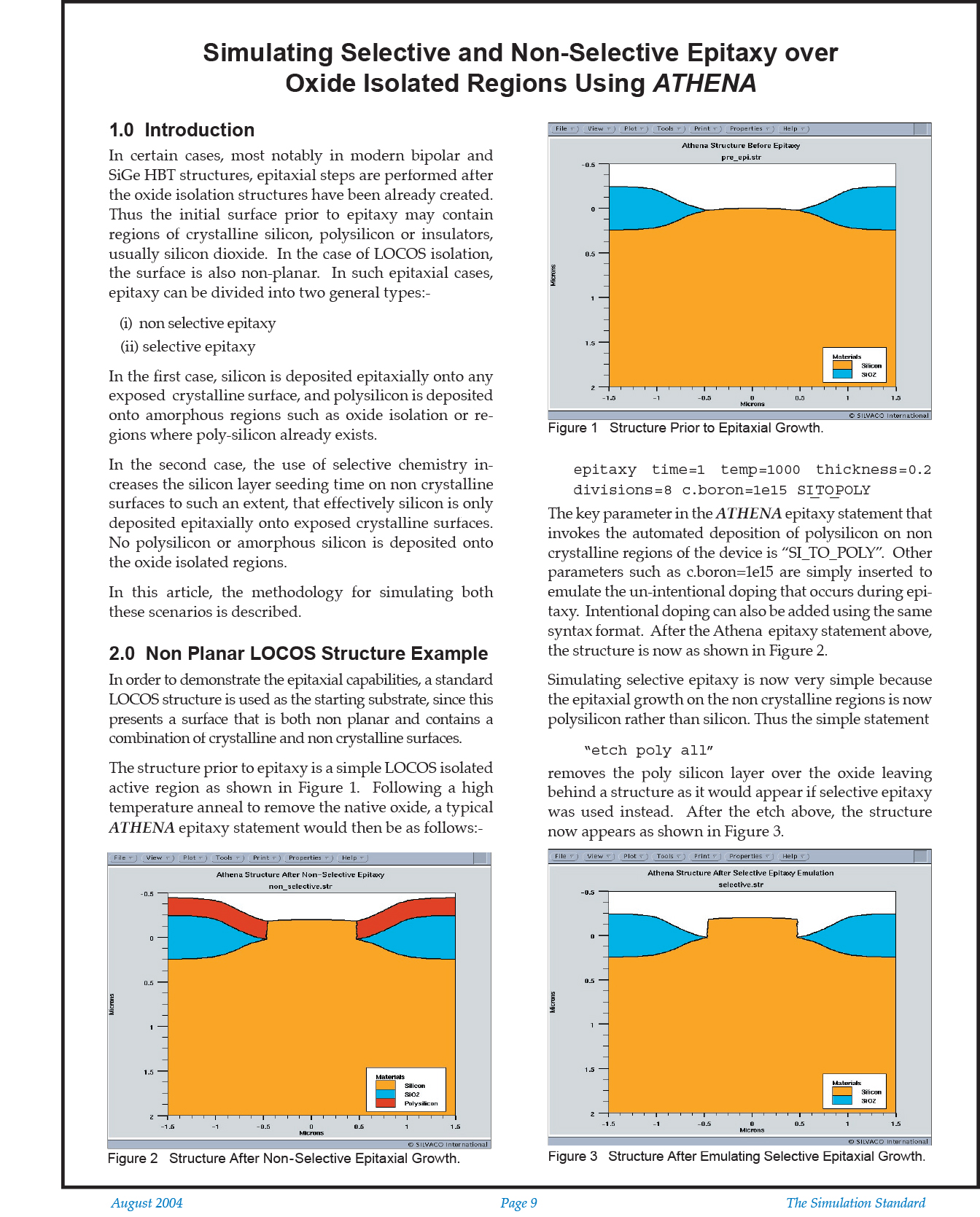

In order to demonstrate the epitaxial capabilities, a standard LOCOS structure is used as the starting substrate, since this presents a surface that is both non planar and contains a combination of crystalline and non crystalline surfaces.

The structure prior to epitaxy is a simple LOCOS isolated active region as shown in Figure 1. Following a high temperature anneal to remove the native oxide, a typical ATHENA epitaxy statement would then be as follows:-

epitaxy time=1 temp=1000 thickness=0.2 divisions=8 c.boron=1e15 SI_TO_POLY