Simulation Standard

Technical Journal

A Journal for Process and Device Engineers

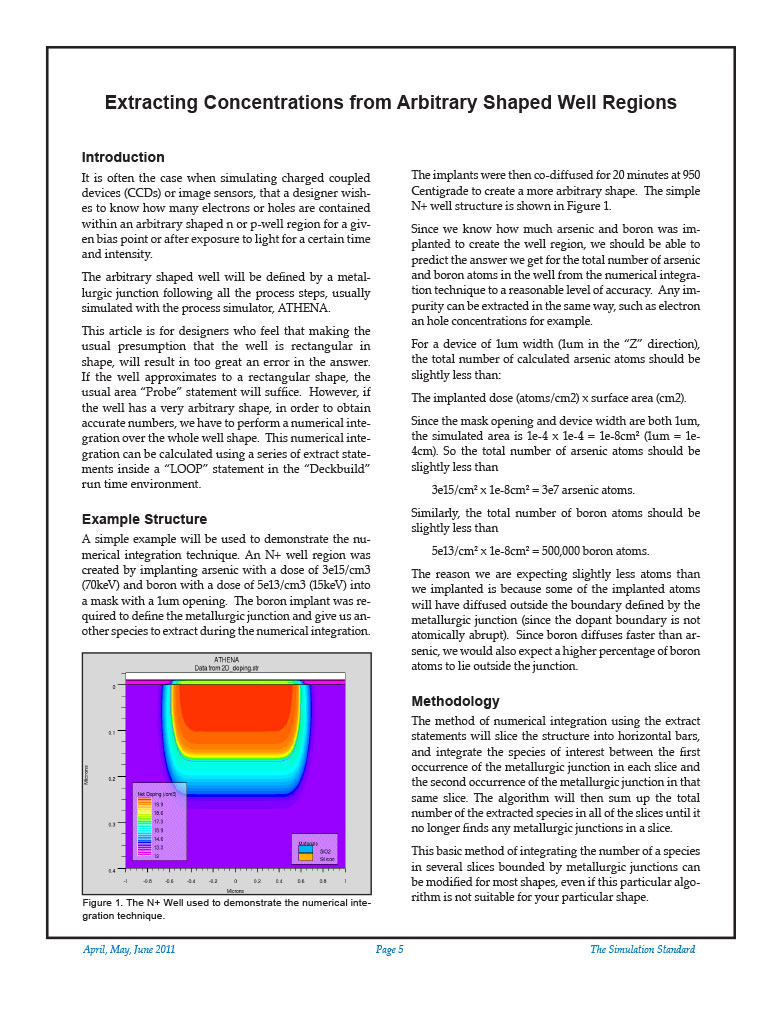

Extracting Concentrations from Arbitrary Shaped Well Regions

It is often the case when simulating charged coupled devices (CCDs) or image sensors, that a designer wishes to know how many electrons or holes are contained within an arbitrary shaped n or p-well region for a given bias point or after exposure to light for a certain time and intensity.

Simulation of 3D Anisotropic Crystal Etching with VICTORY Process

Anisotropic crystal etching is the common technique used in Micro Electromechanical systems (MEMS) manufacturing. It uses the property of some single crystal materials, like silicon, of having different etching rates in different crystal directions when the material is etched in special chemicals, such as potassium hydroxide (KOH). Predicting the resulting shape of the structure under such conditions requires full three-dimensional simulation of the evolution of the etched surface.

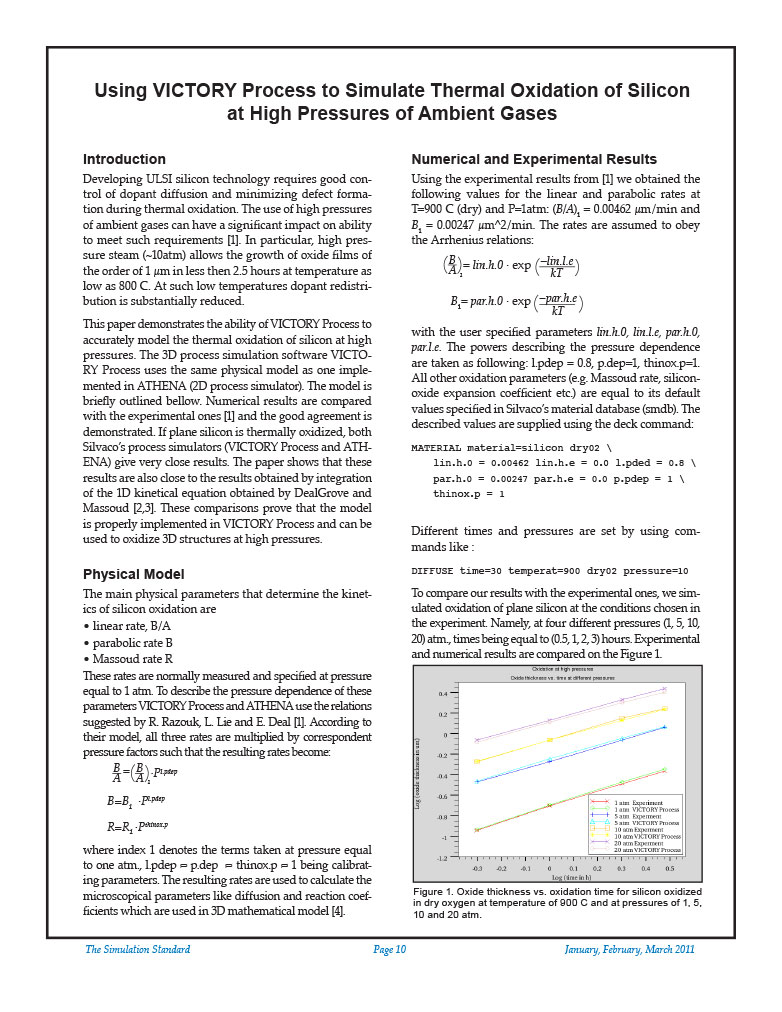

Using VICTORY Process to Simulate Thermal Oxidation of Silicon at High Pressures of Ambient Gases

Developing ULSI silicon technology requires good control of dopant diffusion and minimizing defect formation during thermal oxidation. The use of high pressures of ambient gases can have a significant impact on ability to meet such requirements [1]. In particular, high pressure steam (~10atm) allows the growth of oxide films of the order of 1 μm in less then 2.5 hours at temperature as low as 800 C. At such low temperatures dopant redistribution is substantially reduced.

Hints, Tips, and Solutions – Export 3D Structures from VICTORY Cell/Process to ANSOFT ANSYS

SILVACO provides the tool ANSYSExporter which establishes the link between SILVACO software and ANSOFT ANSYS. ANSYSExporter is fully integrated within the SILVACO environment and can be called by means of a deck statement from DeckBuild or used as a stand-alone tool via command line.

The Doping Effect Simulation on the OLED Devices Using ATLAS

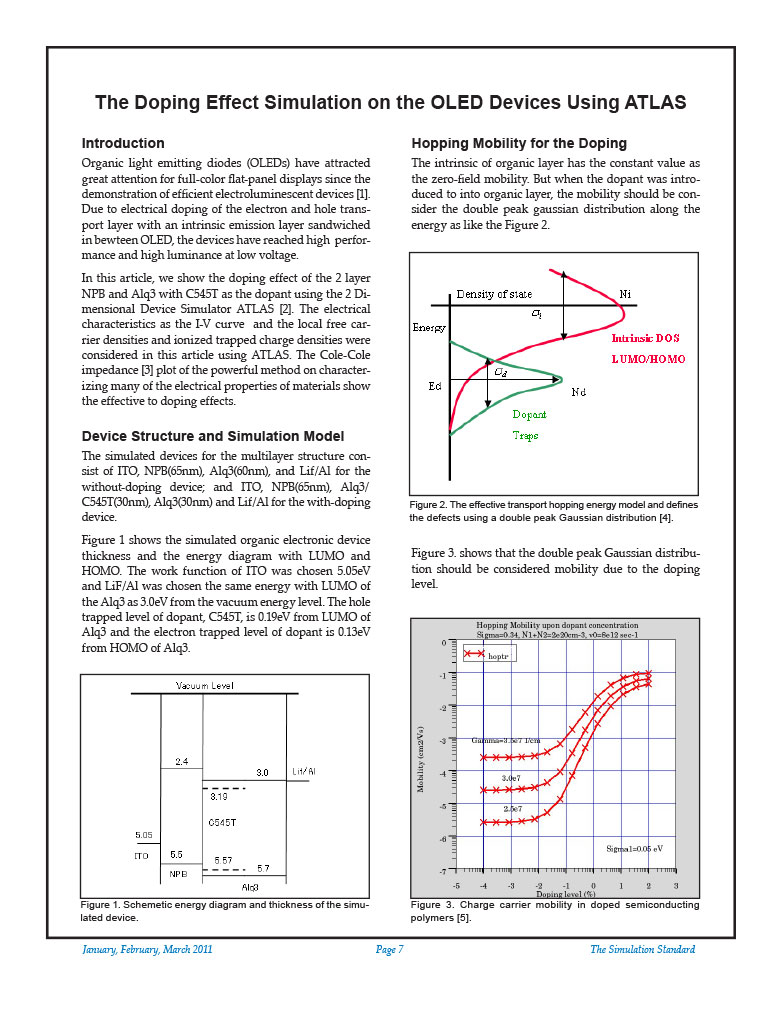

Organic light emitting diodes (OLEDs) have attracted great attention for full-color flat-panel displays since the demonstration of efficient electroluminescent devices [1]. Due to electrical doping of the electron and hole transport layer with an intrinsic emission layer sandwiched in bewteen OLED, the devices have reached high performance and high luminance at low voltage.

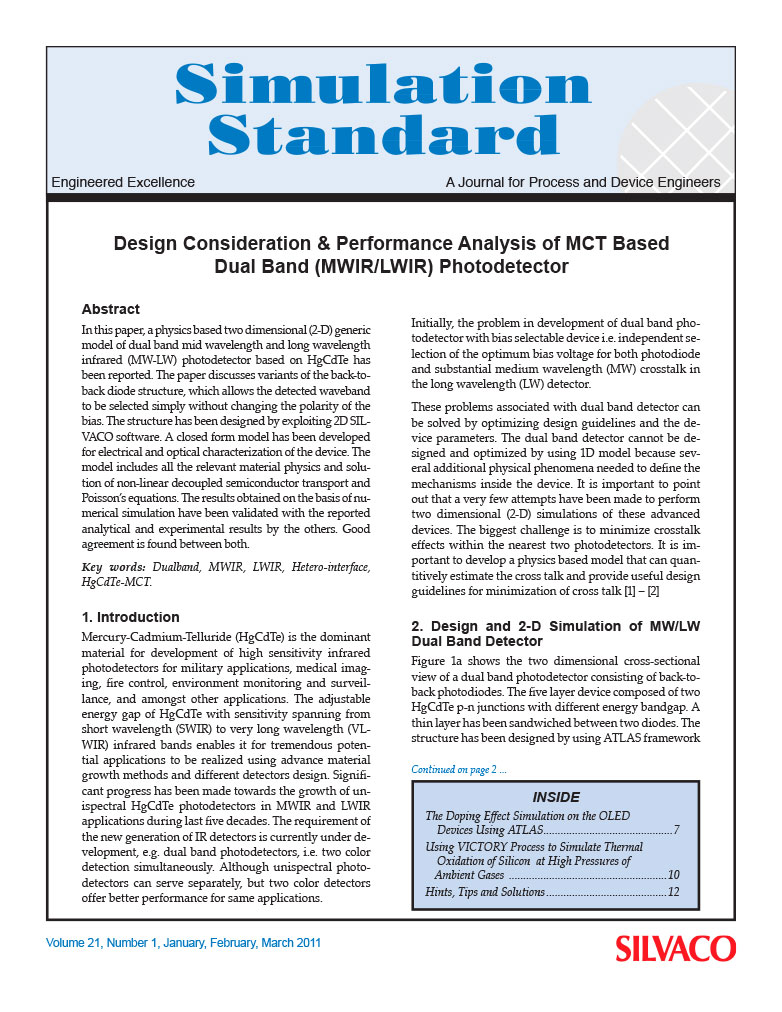

Design Consideration & Performance Analysis of MCT Based Dual Band (MWIR/LWIR) Photodetector

In this paper, a physics based two dimensional (2-D) generic model of dual band mid wavelength and long wavelength infrared (MW-LW) photodetector based on HgCdTe has been reported. The paper discusses variants of the back-to-back diode structure, which allows the detected waveband to be selected simply without changing the polarity of the bias. The structure has been designed by exploiting 2D SILVACO software. A closed form model has been developed for electrical and optical characterization of the device. The model includes all the relevant material physics and solution of non-linear decoupled semiconductor transport and Poisson’s equations. The results obtained on the basis of numerical simulation have been validated with the reported analytical and experimental results by the others. Good agreement is found between both.