Multi-layer Organic Light Emitting Diode Simulation

A conventional 2 layer organic light emitting diode consists of a Hole Ttransport Layer (HTL) and an electron transport layer (ETL). A good OLED structure requires sufficient carrier injection so that large exciton density is generated when the carriers recombine. However, a 2-layer OLED structure has a low injection current due to the poor metal/organic material interface and therefore has a low device output efficiency. The electron injection current can be increased by using a different cathode material such as LiF/Al. Unfortunately, LiF/Al metal processing is hard to control and is very sensitive to processing conditions. Also, hole injection is limited by the ITO anode which has a large metal/organic barrier.

Recent advances to higher injection current has been made possible by using a p-i-n structure[1] which high p-doping in the hole transport layer, high n-doping in electron transport layer and a dopant-host emission layer(EML). By selecting the dopant in the EML, red, green and blue OLEDs can be made. The ouput efficiency can be improved by good metal/organic injection processing.

So far, organic light emitting diode simulations have been used to simulate hole-only or electron-only unipolar devices or simple 2-layer structures. These simple devices can easily be simulated and effects such as hole injection, bulk transport, and electron-hole recombination at the HTL/ETL interface can be analyzed. Commercial OLED structures are multi-layer, so it is necessary to understand the basic principles of organic/organic interfaces as well.

In this article, we examine a 3-layer OLED and show why it has a higher device efficiency than 2-layer OLEDs

Hole Only Device

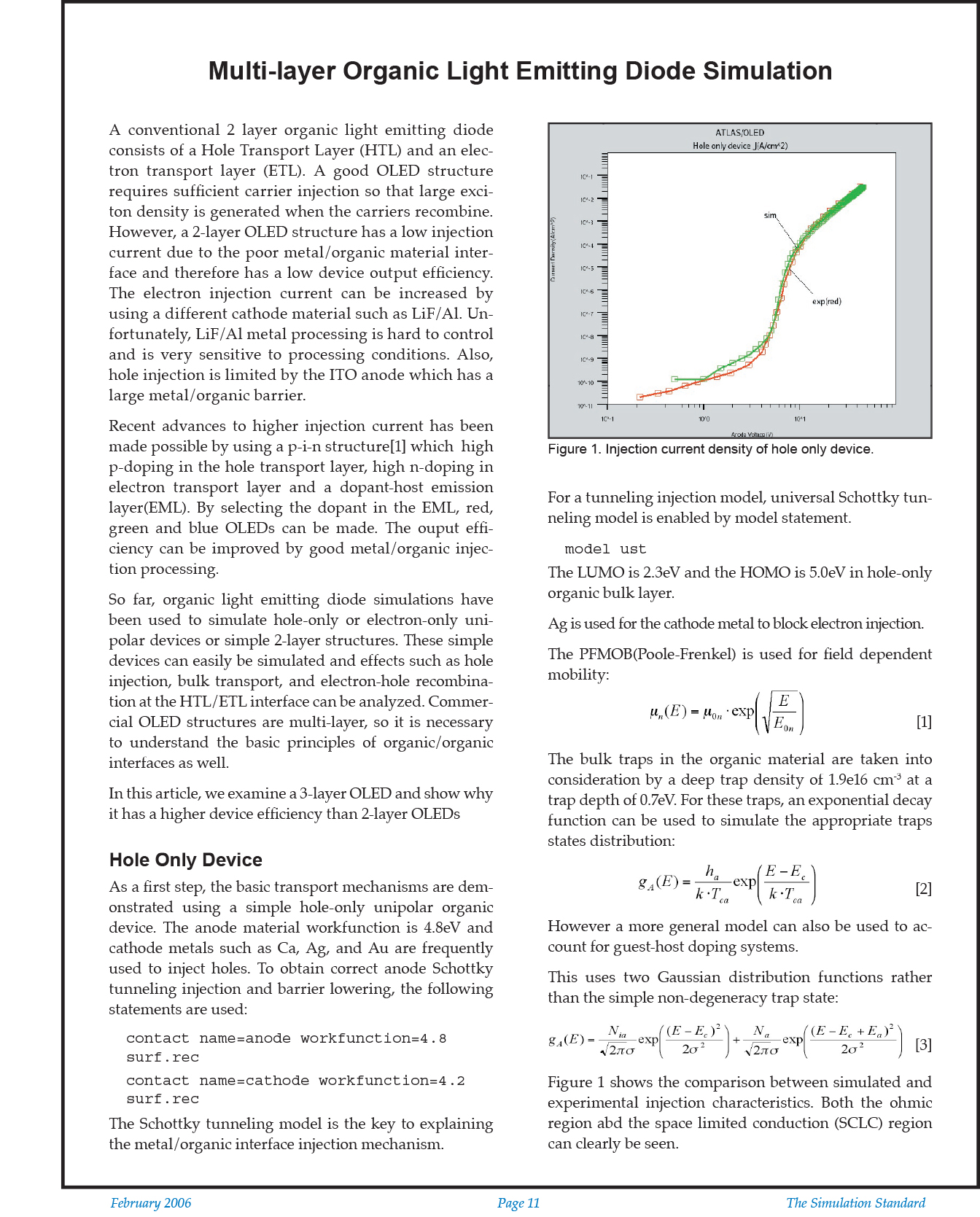

As a first tep, the basic transport mechanisms are demonstrated using a simple hole-only unipolar organic device. The anode material workfunction is 4.8eV and cathode metals such as Ca, Ag, and Au are frequently used to inject holes. To obtain correct anode Schottky tunneling injection and barrier lowering, the following statements are used:

contact name=anode workfunction=4.8 surf.rec

contact name=cathode workfunction=4.2 surf.rec